Expansion of Hong Kong International Airport into a Three-Runway System |

|

|

Section Title

Appendices

Appendix A. Requirements for Contract-Specific Spill Response Plan

Tables

Figures

1

Introduction

|

1.1

Background

Under the Environmental Impact Assessment Ordinance, the Environmental Impact Assessment (EIA) Report (Register No.: AEIAR-185/2014) prepared for the “Expansion of Hong Kong International Airport into a Three-Runway System” (the project) has been approved by the Environmental Protection Department (EPD), and an Environmental Permit (Permit No.: EP-489/2014) has been issued for the project. Pursuant to Condition 2.16 of the Environmental Permit (EP), the Airport Authority Hong Kong (AAHK) shall prepare a Spill Response Plan to handling any spillage incidents related to the project.

Mott MacDonald Hong Kong Limited (MMHK) was appointed by AAHK to provide environmental consultancy services to establish a Spill Response Plan (SRP) for actions to be taken to protect water quality and marine ecology in the event of accidental spillages associated with the project.

1.2

Project Description

This project covers the expansion of the existing airport into a three-runway system (3RS) with key project components comprising land formation of about 650 ha and all associated facilities and infrastructure including taxiways, aprons, aircraft stands, a passenger concourse, an expanded Terminal 2, all related airside and landside works and associated ancillary and supporting facilities.

1.3

Purpose & Scope

As specified in Condition 2.16 of the EP:

“The Permit Holder shall, no later than 3 months before the commencement of construction of the Project, deposit 3 hard copies and 1 electronic copy of a Spill Response Plan (the Plan) detailing the actions to be taken in the event of accidental spillage of oil, unexpected release of large amount of suspended solids or other hazardous chemicals during the construction and operation of the Project, with the Director. The Plan shall include vessels operating for the Project, with specific provisions for protecting water quality and marine ecology as well as for the neighbouring residents.”

1.3.1

Construction Phase SRP

The construction phase SRP, presented in Sections 2 to 7, details the arrangements for effective emergency preparedness and response to spillage incidents during the 3RS Project construction phase for implementation by all Contractors under the 3RS Project, and has been prepared in accordance with the EP requirements. In addition to fulfilling the EP requirements, this Plan also serves to provide the guidelines for setup of contract-specific SRPs by individual Contractors. In particular, this Plan covers the following:

¡ The requirements for the Emergency Team to be setup by each Contractor;

¡ The types of spills that may arise due to project activities;

¡ The requirements for spill prevention measures to be implemented;

¡ The procedures to be followed for timely and effective responses to different types of spill incidents;

¡ The requirements for spill cleanup and reporting;

¡ Specific measures to protect sensitive receivers from adverse impacts due to spills;

¡ The requirements for spill response training and spill response equipment; and

¡ A contact list of relevant parties to be notified in the event of spills.

1.3.2

Operational Phase SRP

Regarding the 3RS operational phase, the arrangements for effective emergency preparedness and response to spillage incidents are covered separately in Section 8.

1.4

Report Structure

Following this introductory section, this SRP is structured as follows:

Construction Phase SRP

Section 2 Roles and Responsibilities

Section 3 Types of Spills

Section 4 Spill Prevention Measures

Section 5 Spill Response Procedures

Section 6 Spill Response Plan Implementation

Section 7 Relevant Parties Contact List

Operational Phase SRP

Section 8 Operational Phase Spill Prevention and Response

2

Roles

and Responsibilities

|

2.1

General

Prevention and spillage response actions are the responsibility of Contractors operating in each construction works area. Proposed organisation arrangements for Contractors and the responsibilities of their key personnel during an emergency spill response event are described in this section.

2.2

Overall Spill Response Arrangements

AAHK as the project proponent and EP holder will assume overall responsibility for the project. In accordance with EP Conditions 2.2 and 2.3, AAHK will employ a full time on-site Environmental Team (ET) and Independent Environmental Checker (IEC) to implement and verify the environmental monitoring and auditing (EM&A) programme and performance respectively. This SRP details the general arrangements and expectations for spill response preparedness for the 3RS Project. During the 3RS construction phase, the responsibility for spill response is delegated by AAHK to individual Contractors undertaking the various construction works packages. Contractors are required to develop their own individual SRPs based on the specific nature of their works making reference to the general requirements and arrangements specified in this Plan. The ET, acting on AAHK’s behalf, will have the role of checking that individual Contractors develop contract-specific SRPs in accordance with the general and specific requirements, including certifying the contract-specific SRPs and thereafter will ensure that plans are properly implemented as part of the EM&A programme. The IEC will have the role of verifying each contract-specific SRP and thereafter auditing the implementation of the contract-specific SRPs as part of the EM&A programme. Under this SRP and any contract-specific SRPs, the central contact of AAHK will take the responsibility for correspondence with relevant Government Departments in the event of handling all kinds of emergency spillage incidents.

2.3

Emergency Team

Personnel

The general requirements of the Emergency Team to be provided by each Contractor are presented below. Each Contractor will be required to prepare a contract-specific SRP and establish their own Emergency / Spill Response Team, with details to be included in their individual plans. Individual Contractors shall prepare their contract-specific SRP based on the general requirements specified in this Plan, with further details set out in Appendix A.

2.3.1

Emergency Team Leader

The Contractors shall designate an Emergency Team Leader, whom shall be a person of sufficient authority with direct responsibilities for the contracted works of the Contractors under 3RS project (such as a Project / Site Manager). The Emergency Team Leader’s main responsibilities should include the following:

¡ Ensure the contract-specific SRP is issued and followed by all construction workers of the project.

¡ Ensure that all construction workers perform their tasks and duties safely and correctly with sufficient resources.

¡ Direct the Emergency Team during any spill event.

¡ Maintain communication with AAHK and other relevant external parties in the event of spillage as mentioned in this SRP.

2.3.2

Emergency Team

The Emergency Team shall comprise appropriate personnel (such as Safety Manager, Environmental Manager and/or Environmental Officer) to coordinate, monitor and oversee the implementation and performance of the SRP and shall assist the Emergency Team Leader when any spillages occur. The Emergency Team shall liaise with the ET / IEC via the communication channels established by AAHK for the 3RS project. The Emergency Team shall ensure that all construction workers follow the requirements of the contract-specific SRP and shall provide related spill prevention and response training to all construction workers. The Emergency Team shall conduct a spill incident / accident investigation when required, and shall review and update the SRP on a regular basis.

The Contractors shall provide full details of the individual personnel comprising their Emergency Team, including individual roles, responsibilities, lines of communication and an organisation chart in their contract-specific SRP.

2.3.3

Onsite Workers

All onsite construction workers are responsible for complying with the SRP and following the instructions of the Emergency Team. All workers are required to attend training provided by the Emergency Team to ensure construction materials, chemicals and wastes are handled and stored properly onsite as required by the EIA and the SRP. Workers are required to implement any remedial actions or environmental protection measures as directed by the Emergency Team, with proper use of the spill kits to collect and store the spillage wastes generated during cleanup of any spills where applicable. Workers are also responsible for reporting immediately to the Emergency Team any incidences that occurred during the site works.

3

Types

of Spills

|

3.1

Key Types of Spills

Based on the construction phase activities associated with the 3RS project, the key types of spillages that may arise due to the project are summarised in Table 3.1.

Table 3.1: Key types of spills that may arise due to construction of 3RS project

|

|

Construction Phase |

|

|

Spill Types |

Land-based Activities |

Marine-based Activities |

|

Fuel / oil |

ü |

ü |

|

Chemicals |

ü |

ü |

|

Fill materials |

n/a |

ü |

Further details of these different types of spills are presented below.

3.1.1

Land-Based Spills from Land-Based Activities

The main types of the spills that may arise from land-based activities are spillage of fuel / oil and chemicals.

Fuels / oils used during operation of powered mechanical equipment or stored onsite may be accidentally spilled due to poor handling practices or when insufficient safeguards are provided. While land-based spills are likely to be confined to the immediate area of the spill, the spill may seep into nearby stormwater drains and discharge into the marine environment if not responded to immediately.

Chemicals used during construction phase include construction materials such as bentonite and cement, finishing materials such as paints and coatings, and plant maintenance chemicals such as lubricants and solvents. Similar to fuel / oil spills, spillage of chemicals are likely to be confined to the immediate area of the spill, but may seep into nearby stormwater drains and discharge into the marine environment if not responded to immediately.

For fill materials used during construction phase, only accidental spillages into the marine environment are identified as a potential concern.

3.1.2

Marine Spills from Marine-Based Activities

The main types of the spills that may arise from marine activities are spillage of fuel / oil, chemicals and construction fill materials.

Similar to land-based activities, fuel / oil and chemicals may be stored onboard construction / working vessels and can be accidentally spilled due to poor handling practices or when insufficient safeguards are provided against unforeseen events such as vessel collision. Any spills into the marine environment can form a large plume quickly due to wave and current action unless it is isolated quickly.

Spillage of construction fill materials may arise during transport of the materials to the construction area, and during filling activities for land formation. Spillage of fill materials can form large sediment plumes due to wave and current action unless it is isolated quickly.

4

Spill

Prevention Measures

|

4.1

General Precautions

The following general precautionary measures shall be applied to all construction works areas to minimise the risk of accidental spillage:

¡ Maintain good site housekeeping practices and ensure all materials, chemicals and wastes are properly stored and placed in appropriate disposal areas onsite at the end of each day.

¡ Avoid disorder and storage of unnecessary materials in working areas.

¡ Open flames and smoking shall be prohibited within the construction site; smoking may be permitted only at designated smoking areas.

¡ Stacked containers should be secured from falling.

¡ Large / heavy containers should be stored on the floor as far as possible to prevent falling.

¡ Warning signs, fences and locks where appropriate should be deployed for storage place of hazardous materials, chemicals, fuel and oil, etc.

4.2

Construction

Materials

Unexpected release of large amounts of suspended solids, in case of accidents, human negligence or mechanical failure would result in adverse water quality and marine ecology impacts. Hence, precaution and prevention measures are required to minimise the risk of such accidental spills. The following measures shall be applied to all construction vessels involving transport of materials that may give rise to unexpected release of large amounts of suspended solids:

Prior to transport of fill materials;

¡ Bottom opening of barges shall be fitted with tight fitting seals to prevent leakage of material.

¡ Vessels shall be regularly inspected to ensure no leakages and any leakages shall be repaired quickly prior to mobilisation of the vessels.

¡ Barges or hoppers shall not be filled to a level which will cause overflow of materials or pollution of water during loading or transportation.

¡ Excess materials shall be cleaned from the decks and exposed fittings of barges and hopper dredgers before the vessels are moved.

¡ Adequate freeboard shall be maintained on barges to reduce the likelihood of decks being washed by wave action.

During transport;

¡ Vessels shall follow the pre-defined routes and marine traffic arrangements to minimise the risk of collision.

¡ Vessels shall follow the designated entry / exit points into and out of the construction site boundary.

¡ Vessel speeds shall be limited to 10 knots or less within the construction works area and hotspots of the Chinese White Dolphins (CWDs).

¡ Transits of vessels operating within the construction works areas will be monitored and managed by a Marine Traffic Monitoring System (MTMS) associated with a 24-hour On-shore Control Room, which will be established by AAHK for the project. Details of this MTMS have been stipulated in the separate Marine Travel Routes and Management Plan for Construction and Associated Vessels pursuant to EP Condition 2.9.

During filling activities for the land formation works;

¡ Pipes and fittings connecting the barges with the spreaders shall be properly fitted and checked for leakages / loose fittings prior to transferring any fill materials.

¡ Pipes shall be sized according to the required pumping rates and the pumping rates shall not exceed the pressure limits of the pipes / connections.

¡ During marine excavation activities for the submarine 11kV cable field joint excavation, and piling activities for the runway approach lights and Hong Kong International Airport Approach Area marker beacons, only closed grabs designed and maintained to avoid spillage shall be used and should seal tightly when operated.

4.3

Chemicals, Oils

and Fuels

For chemicals, oils and fuels required and used onsite, the following measures shall be applied:

For procurement;

¡ Label all chemical storage containers and tanks in accordance with the EPD ‘Code of Practice on the Package, Labelling and Storage of Chemical Wastes’.

¡ An up to date list of chemicals, chemical waste and fuel oil should be maintained.

For storage;

¡ Suitable containers should be used which are resistant to the stored oil fuel, chemical / chemical waste to avoid leakage.

¡ Containers should be checked before use and container lids should be closed tightly to avoid leakage of chemicals and chemical waste.

¡ Chemical waste storage areas should be located in a designated area that is sheltered on at least 3 sides and the top, and is locked and kept clean and free from obstruction.

¡ Incompatible chemicals should be separated.

¡ Chemical, oil and fuel containers should be kept under eye level as far as possible.

¡ Drip trays or bunds should be used for storage containers of chemicals and oil / fuel tanks and should have a capacity equal to 110 % of the storage capacity of the largest tank.

¡ Chemical storage area and drip trays should be inspected daily to ensure the containers are in good condition and there are no openings which oil / chemicals can possibly leak out. Any damage / openings to the storage area and drip trays should be repaired or replaced immediately.

¡ Where chemicals are temporarily taken outside the sheltered chemical storage area, the chemicals including the drip trays / bund should be covered by waterproof tarpaulins and kept free of rainwater.

For transfer / transport;

¡ Pumps should be used to transfer large quantities of oil, fuel, chemical / chemical wastes instead of pouring.

¡ Oil, fuel, chemical / chemical wastes should be transferred slowly to prevent spillage or overfilling.

¡ Suitable trolley should be used to transport chemicals / chemical wastes to other location.

For use;

¡ Chemical quantities / dosage required during each use shall be carefully calculated / measured to prevent any excess chemicals being generated and released.

¡ Drilling fluid used in drilling activities should be reconditioned and reused as far as possible.

5

Spill

Response Procedures

|

5.1

General

In the event of a spillage incident, the spill response needs to be carried out promptly and efficiently according to the spillage location, type of spill and quantity of spill. An effective spill response can prevent adverse impacts to the environment and may also minimize the quantity of release into the environment. The spill responses for different spillage types and scenarios are discussed in the following sections.

5.2

Construction

Phase Spill Response

When a spill occurs, the individual identifying the spill shall inform the Emergency Team to proceed with the appropriate spill response immediately. The individual shall report the following to the Emergency Team:

¡ The location of the spill;

¡ Nature of the affected location (e.g. concrete, dirt, marine environment);

¡ When the spill occurred;

¡ The type of spill (e.g. oil, chemical, hazardous materials, suspended solid); and

¡ The approximate quantity and size of the spill.

For chemicals and hazardous materials, the name of the chemical / hazardous material should also be identified and reported immediately as part of the emergency communication. After receiving the description of the spill from the workers, the Emergency Team shall proceed with the appropriate spill response according to the relevant scenario described below.

5.2.1

Oil or Hazardous Chemicals Spill on Land or on Deck of

Marine Vessel

Immediate response

1. Workers shall take immediate measures (in line with spill response training) to stop the source of the spill if the source is obvious and it is safe to do so, and inform the Emergency Team of the spill incident.

2. Emergency Team Leader / Members shall organize the manpower to identify / check the source of the spill and provide instructions for stopping / containing the spill.

3. Workers shall stop, reduce, isolate or contain the spillage if possible measures can be taken (e.g. turn off the valve).

4. In parallel, the Emergency Team Leader shall inform all relevant parties such as AAHK, ET and IEC immediately and keep such parties informed throughout the spill response.

5. If the spill spreads to an area larger than 100m2, the Emergency Team Leader shall also inform all relevant authorities such as EPD and Fire Services Department (FSD) immediately, and keep such parties informed throughout the spill response.

Spill response (for spillage area less than 100m2)

6. Workers shall install forced ventilation to ensure a safe spillage response condition is provided, where applicable.

7. Emergency Team shall appoint well-trained cleanup crew to cleanup the spillage area.

8. Emergency Team shall review relevant Material Safety Data Sheet (MSDS) for the chemical spill. The MSDS would have specific instruction on how to deal with chemical spill.

9. Emergency Team shall ensure all the workers involved in the cleanup works are equipped with suitable personal protective equipment (PPE).

10. The spilt material shall be put back into the containers of origin if possible and practical. Otherwise, dry sand, sawdust or other suitable materials shall be used to absorb the spill.

11. Any contaminated materials shall be collected, bagged and clearly marked as “Chemical Waste”.

12. All collected chemical waste shall be stored in a designated chemical waste area and handled and disposed of in accordance with the Waste Disposal (Chemical Waste) Regulations.

13. Emergency Team shall carry out spill investigation and complete the spill incident report.

Spill response (for spillage area greater than 100m2)

1. Follow item nos. 6 to 12 of the procedures for spill responses for spillage area less than 100m2

2. The ET and Emergency Team shall carry out joint spill investigation and complete the spill incident report with provisions for improvement measures / practices to prevent re-occurrence and update this SRP if necessary. The improvement and prevention measures/practices should be recommended to AAHK. Site staff shall be briefed of these measures by the Emergency Team after the investigation.

5.2.2

Oil or Hazardous

Chemicals Spill into Marine Environment

When oil or other hazardous materials are spilt into the marine environment, the spill could be spread out quickly due to the water current and wind speed. Therefore, a timely and effective spill response shall be implemented in order to minimize the impacts to the marine environment.

Immediate response

1. Workers shall take immediate measures (in line with spill response training) to stop the source of the spill if the source is obvious and it is safe to do so, and inform the Emergency Team of the spill incident.

2. Emergency Team Leader / Members shall organize the manpower to identify / check the source of the spill and provide instructions for stopping / containing the spill.

3. Workers shall stop, reduce, isolate or contain the spillage if possible measures can be taken (e.g. deploy containment booms).

4. In parallel, the Emergency Team Leader shall inform all relevant parties such as AAHK, ET and IEC immediately and keep such parties informed throughout the spill response.

5. If the spillage spreads to an area larger than 100m2, the Emergency Team Leader shall also inform all relevant authorities such as EPD, Marine Department (MD), Agriculture Fisheries and Conservation Department (AFCD), and Fire Services Department (FSD) immediately, and keep such parties informed throughout the spill response.

Spill response (for spillage area less than 100m2)

6. Emergency Team shall appoint well-trained cleanup crew to cleanup the spillage area;

7. Emergency Team shall ensure all the workers involved in the cleanup works are equipped with suitable PPE;

8. Absorption materials such as pads or pillow shall be used to absorb the spillage;

9. Any contaminated materials shall be collected and put in a spill containment and clearly marked as “ Chemical Waste”;

10. All collected chemical waste shall be stored in designated chemical waste area and handled and disposed of in accordance with the Waste Disposal (Chemical Waste) Regulations;

11. The ET shall review whether additional water quality monitoring is necessary to ascertain whether the spill has resulted in any exceedances at nearby sensitive receivers;

12. Emergency Team shall carry out spill investigation and complete the spill incident report with provision of improvement and prevention measures recommended to AAHK. Site staff shall be briefed of these measures by the Emergency Team after the investigation.

Spill response (for spillage area greater than 100m2)

1. Follow item nos. 6 to 11 of the procedures for spill responses for spillage area less than 100m2.

2. Implement the specific dolphin contingency as per Section 5.3 and the procedures for protection of sensitive receivers as per Section 5.4;

3. The ET and Emergency Team shall carry out joint spill investigation and complete the spill incident report with provisions for improvement measures / practices to prevent re-occurrence and update this SRP if necessary. The improvement and prevention measures/ practices should be recommended to AAHK. Site staff shall be briefed of these measures by the Emergency Team and such measures shall be included in future drills and exercise.

4. A report of the spillage incident, including the investigation report and recommended improvement measures should be provided to EPD.

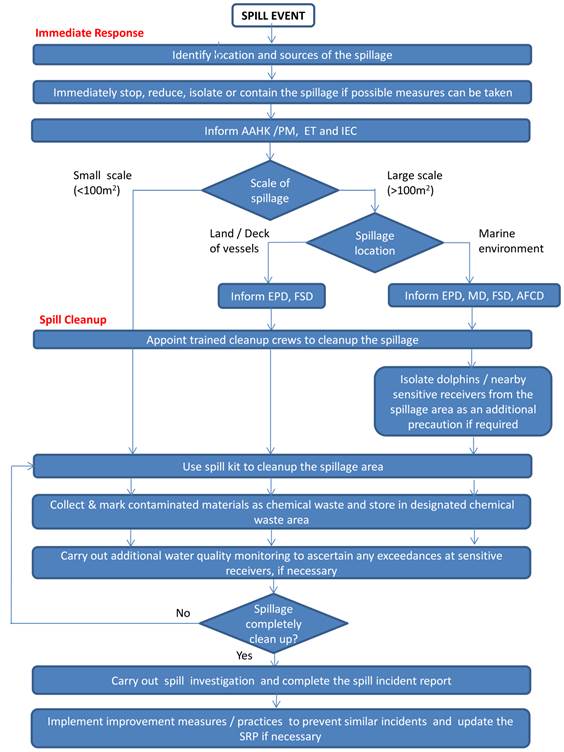

The overall process for oil and hazardous chemicals spill procedures is presented in Figure 5.1.

|

Figure 5.1: Overall Oil / Hazardous Chemicals Spill Response Procedure

|

|

|

5.2.3

Suspended Solids (SS) Spill into Marine Environment

According to the EIA, with the implementation of the required mitigation measures for SS release (which includes using non-dredge construction methods, deployment of silt curtains, control of fines content and production rates, etc.) the potential for adverse water quality impact due to SS release during construction phase is considered to be insignificant.

Nevertheless, if a large amount (>10% of the storage capacity of the vessel) of sand / public fill material is unexpectedly released into the marine environment during transport of the materials outside the construction site boundary, the individual identifying the spill shall inform the Emergency Team to proceed with the appropriate spill response immediately as follows:

1. Emergency Team shall take immediate measures (in line with spill response training) to stop the source of the spill if the source is obvious and it is safe to do so;

2. Emergency Team Leader shall inform all relevant parties such as EPD, AAHK, ET and IEC immediately and keep such parties informed throughout the spill response;

3. Emergency Team Leader shall provide all details of the spill to the ET;

4. The ET shall undertake a rapid spill evaluation to identify (based on spill location, quantity, type of material, tidal conditions and proximity to sensitive receivers) whether any sensitive receivers are immediately at risk from the SS release, and recommend appropriate mitigation measures (e.g. deployment of temporary silt curtains at sensitive receiver locations) to AAHK and IEC accordingly;

5. The Emergency Team Leader shall immediately implement the mitigation measures as requested by the AAHK based on the ET’s rapid spill evaluation;

6. The ET shall review existing monitoring data and conduct additional monitoring if necessary to ascertain whether the spill has resulted in any exceedances at nearby sensitive receivers (if the rapid spill evaluation has identified sensitive receivers to be at risk from the SS release);

7. The ET shall identify the need for any further mitigation measures in consultation with the AAHK and IEC;

8. The Emergency Team Leader shall implement the further mitigation measures as requested by the AAHK;

9. The ET shall review the effectiveness of the Contractor’s mitigation measures and the updated situation until such time as all sensitive receivers show no exceedance in SS levels;

10. The Emergency Team shall assist the ET to prepare a spill investigation report to identify the cause / reason for the spill and the improvement measures / practices to prevent re-occurrence, and update this SRP if necessary.

5.3

Dolphin

Contingency Plan

CWDs are commonly found within western waters of Hong Kong. If a spill of oil / hazardous chemicals occurs in the marine environment and spreads over a large area, the health and wellbeing of CWDs might be endangered. As such, a Dolphin Contingency Plan shall be implemented for large scale oil / hazardous chemicals spills released into marine environment.

When a large scale (greater than 100m2) spill occurs, the individual identifying the spill shall inform the Emergency Team to proceed with the Dolphin Contingency Plan immediately as follows:

1. The Emergency Team shall determine the location and approximate extent of the spill from a high platform;

2. The dolphin observers shall check whether any CWDs are present in the vicinity of the spill, if possible;

3. The Emergency Team Leader shall ensure the appropriate spill response measures are implemented. These may include:

a. Containment booms to minimise the spread of spill. This helps to prevent the CWDs from coming into contact with the spill and can act as a visual barrier to prevent the CWDs from entering the contaminated area;

b. Underwater barrier nets to isolate the CWDs from the spill area, if necessary; and

c. Absorption materials such as pads or pillow to cleanup the spillage as soon as possible.

4. During deployment of the spill response measures, the dolphin observers shall maintain visual contact with any CWDs sighted in the area to ensure the CWDs are not trapped behind the contained areas;

5. The dolphin observers shall maintain watch of the spillage area until the spill is completely cleaned up. If dolphins are found to be entering into the contained spillage areas, the Emergency Team Leader / Emergency Team shall contact the ET and seek their advice for appropriate actions.

5.4

Sensitive

Receivers

When a large scale spill occurs, the following procedures shall be taken in order to protect sensitive receivers within the vicinity of the project site:

1. The Emergency Team shall implement all possible mitigation measures in order to isolate the spill and minimize any potential adverse impacts to the sensitive receivers.

2. The Emergency Team Leader shall immediately inform the relevant parties as mentioned in Section 5.2.

3. Potentially affected sensitive receivers such as seawater intakes, ecological sensitive receivers, fisheries and fish culture zones, corals and bathing beaches shall be identified by the ET.

4. The Emergency Team Leader shall immediately implement any at receiver mitigation measures as requested by the AAHK based on the ET / IEC’s recommendations. This may include deployment of absorbent booms or other similar booms in order to surround and protect the sensitive receivers.

5. The ET shall implement additional water quality monitoring if necessary to determine any potential adverse impacts to the sensitive receivers and the need for any further mitigation measures.

6. The Emergency Team Leader shall implement any further mitigation measures as requested by the AAHK based on the ET / IEC’s recommendations.

7. The ET shall continue to monitor the impacts at the sensitive receivers until the spill is completely cleaned up and there is no further adverse impacts to the sensitive receivers (as confirmed by water quality monitoring results).

5.5

Neighbouring Residents

There are no neighbouring residents (i.e. non-airport operations related personnel) located within or immediately adjacent to the 3RS project area that may be affected by spillage events arising from construction of the 3RS project. Hence no specific provisions for protecting neighbouring residents are required.

6

Spill

Response Plan Implementation

|

6.1

Training

All construction site workers shall be introduced to the SRP during the environmental induction training and Tool Box talks which should be carried out by the Contractors for each construction site. During the induction training and Tool Box talks, a demonstration of the containment methods and equipment shall be carried out. The Contractors shall conduct Tool Box talks with the site workers regarding the SRP periodically. Examples of spill related training topics are shown in Table 6.1. The Tool Box talk training material prepared by the Contractors should be submitted to AAHK and reviewed by the ET, and the Contractors should update their materials regularly, if required. The Emergency Team Leader shall ensure that all relevant workers receive the appropriate spill related training prior to undertaking activities that may lead to spillage or involve spill response. A training record shall be maintained by the Contractors to register the training provided and each individual’s signoff to acknowledge that the training has been attended and the content is understood. The training record should be made readily available to the ET and IEC for checking and auditing. Refresher training shall be provided regularly and all relevant workers shall attend and signoff subsequent refresher training at least once every 3 years. Training arrangements for dolphin observers will be detailed in the Marine Mammal Watching Plan under EP Condition 2.11 and a separate Dolphin Exclusion Zone (DEZ) Plan.

Table 6.1: Spill Related Training Topics

|

Training Topic |

Applicable Personnel |

|

Introduction to the SRP and its requirements on spill response |

All construction site workers |

|

Spill prevention and detection |

All construction site workers |

|

Work safety around the spill |

All construction site workers |

|

Containment of spill |

All construction site workers |

|

Recovery and cleanup of spill |

Spill cleanup crew |

|

Handling and disposal of waste generated from spill |

Spill cleanup crew |

6.2

Spill Control Equipment

At least one set of spill kit should be provided and stored onsite near each storage area for chemicals or chemical waste. At least three sets of spill kits should be available aboard each vessel involved in marine works. An additional set of spill kit should be located near the Emergency Team’s office. Additional spill kits should also be provided onsite at locations or activities with a higher risk of spills. The Contractor shall ensure that sufficient spill kits are available onsite at all times. The Contractor shall ensure that all workers are aware of the locations of spill kits. The spill kit shall include, but are not limited to the following items:

¡ Oil absorbent pads;

¡ Oil absorbent socks;

¡ Sorbent booms;

¡ Silt curtains;

¡ Sweeps;

¡ Goggles;

¡ Protective masks;

¡ Nitrile gloves;

¡ Disposal bags;

¡ Instruction sheets; and

¡ Diagram of the site plan, including drainage plan of the site and the airport facilities.

Regular (at least quarterly and after each spillage event) inspections and stocktaking of the resource materials in the spill response kit should be taken by the Emergency Team. Regular (at least annually) checking and testing of the functioning and validity date of the resource materials should also be carried out by the Emergency Team.

6.3

Drills

Regular drills would be carried out to ensure all site workers, especially the Emergency Team members, are proficient in his/her assigned duties. Where applicable, spill incidents will be simulated, drilled and practiced at least annually. After commencement of works, Contractor shall provide the drill schedule to AAHK, ET and IEC for audit. Relevant parties including AAHK, ET and IEC, and relevant authorities such as FSD, MD, AFCD and Police would be invited to participate and/or witness the drill exercises.

6.4

Spillage Incident Report

For chemical related spills, the Emergency Team shall prepare a draft spillage incident report for submission to AAHK, ET and IEC within 2 days after the incident occurred. For spills of SS-generating materials (sand or public fill), the Emergency Team shall assist the ET to prepare a draft spillage incident report to AAHK and IEC within 5 days after the incident occurred. The draft incident report should include but are not limited to the following:

¡ Details of the spillage incident;

¡ Clean up actions taken;

¡ Any residues of the spill remaining in the environment;

¡ Follow up or monitoring actions taken if required; and

¡ Photo records.

A full investigation report of the spillage incident shall be submitted to AAHK, ET and IEC within 2 weeks after the incident occurred. In addition to the details of a draft incident report, the full report will investigate the reasons for the spillage and evaluate the effectiveness of the procedures and precautionary measures taken and specified in this SRP. Where applicable, additional mitigation measures will be proposed and implemented to prevent similar occurrence of spillage.

6.5

Information and Recording Keeping

The SRP should be maintained as an easily accessible document onsite as well as in the AAHK’s project office including the office of AAHK’s contact point. Previous spillage incident reports and recommendations should also be kept for reference in case of similar spillage events. All records of self-inspection, checking and testing, drills, and response training should be kept for record and reference.

6.6

Review and Update of the SRP

The spill response procedures in

this SRP should be reviewed after every spill incident and/or spill response

drill, and at least annually, and relevant procedures and measures shall be

updated as required.

7

Relevant

Parties Contact List

|

7.1

Emergency Contacts

The following tables (Table 7.1 - Table 7.4) provide the names and telephone contacts of various parties who should be contacted in case of a spill incident or emergency.

Table 7.1: Project / Environmental Team’s Contact List

|

Role |

Contact No. |

|

Airport Authority Hong Kong |

2188 7807 |

|

Independent Environmental Checker |

3922 9376 |

|

Environmental Team Leader |

2828 5919 |

Table 7.2: Contractor’s Emergency Team Contact List

|

Role |

Contact No. |

|

Emergency Team Leader |

To be specified in each contract-specific SRP |

|

Emergency Team members |

To be specified in each contract-specific SRP |

Table 7.3: Government Department Contact List

|

Government Department |

Contact No. |

|

General Emergency Services |

999 |

|

Labour Department |

2717 1771 |

|

Fire Services Department |

2723 8787 |

|

Agriculture, Fisheries and Conservation Department |

2708 8885 |

|

Environmental Protection Department |

2838 3111 |

|

Marine Department |

2542 3711 |

|

Vessel Traffic Centre |

2233 7808 |

|

Maritime Rescue Coordination Centre |

2233 7999 |

|

Fire Station |

Tung Chung Fire Station: 2988 1898 |

|

Chek Lap Kok Fire Station: 2949 9081 |

|

|

Ambulance |

Tung Chung Ambulance Depot: 2988 8282 |

|

Hospital |

North Lantau Hospital: 3467 7000 |

Table 7.4: Utility Company Contract List

|

Utility Company |

Contact No. |

|

China Light and Power Co. Ltd. |

2728 8333 |

|

China Gas Co. Ltd. |

2880 6999 |

The emergency contact list shall

be reviewed at least annually. Any changes should be amended and notified to

all onsite staff immediately.

8.1

General

In line with the EIA, AAHK is committed to maintaining the same level of spill prevention and spill response as is currently in place under the 2RS operations. This operational phase spill response plan is therefore based on existing spill response procedures in place for the 2RS and these are considered to be valid and applicable. Nevertheless, it should be noted that the final arrangements for the 3RS operational phase spill response are subject to confirmation before commencement of 3RS operations, for example to allow incorporation of details and final arrangements from the detailed designs for 3RS buildings and infrastructure. Therefore, the operational phase SRP will be further updated for it to be ready for use upon commencement of full 3RS operations.

8.1.1

Operational Emergency Spill Response Plan

During the 3RS operational phase, the content of this chapter shall be collated into an Operational Emergency Spill Response Plan to be kept at an easily accessible and signposted location in the Operation Control Centre of the AAHK and made available for EPD's inspection whenever required. The Operational Emergency Spill Response Plan, presenting the updated contents of this chapter, shall include, and/or be kept with, the following:

¡ Detailed 3RS plans, including 3RS drainage details and 3RS airport facilities;

¡ Previous spill reports and recommendations;

¡ Records of self-inspections, checking and testing, drills, and response trainings; and

¡ Records of annual review of staff trainings on emergency response handling for relevant airport staff.

The 3RS Operational Emergency Spill Response Plan shall be updated prior to commencement of full 3RS operations and regularly reviewed and updated thereafter by AAHK.

Details of the operational phase spill prevention and response procedures are as follows.

8.2

Roles and Responsibilities

During the 3RS operational phase, AAHK and/or AAHK’s term maintenance contractor(s) / tenants will be the primary responsible parties for implementing spill prevention and response. Table 8.1 summarises the key roles and responsible tasks of the main parties involved in HKIA spill response.

Table 8.1: Summary of Roles and Responsibilities for Operational Phase Spill Response

|

Responsible Party |

Key Role in Spill Response |

Spill Response-related Tasks |

|

All Spillage Events |

||

|

AAHK |

Alert all parties and oversee the spill response |

Receive reports of fuel / chemical spillage occurring within airport premises and obtain details of the incident. Alert the relevant AAHK Incident Coordinator to mobilise on scene. Alert all other relevant parties including other AAHK Departments / personnel, other Tenants / Airport Operators, and Government Departments where applicable. Assess environmental implications and liaise with Government Departments on any additional mitigation, if required |

|

AAHK Incident Coordinator |

Coordinate and monitor the spill response activities |

On scene liaison with all parties concerned. Monitor response activities to ensure the spill is controlled and contained. Ensure precautionary measures taken by the party responsible for the fuel / chemical spillage to prevent the spill from entering into the storm water drainage system. Liaise with party responsible for the fuel / chemical spillage regarding disposal of the spilt material and subsequent cleanup of affected areas. Liaise with all parties concerned to agree / confirm closeout of the incident / accident. Maintain a log of events and actions taken. |

|

AAHK’s Emergency Team (e.g. AAHK’s Term Maintenance Contractor) |

Provide assistance in spill response activities |

Upon request by the AAHK Incident Coordinator, provide service to contain and clean up the spilt material. Activate contingencies to prevent spilt material from entering the marine environment, if required.

|

|

For Fuel Spillage from Aircraft |

||

|

Into-plane Fuelling Franchisee / Refuelling operator |

Fuel spillage containment, control and clean up |

Immediately stop the fuel flow and notify the Line Maintenance Franchisee and AAHK of the spill. Contain, control and clean up the affected area if the spill is less than 20 litres and not of a running nature. Coordinate with the Line Maintenance Franchisee for containment, control and cleanup of major spills (spills greater than 20 litres or of a running nature). Maintain communication with the AAHK Incident Coordinator. Maintain a log of events and actions taken. |

|

Line Maintenance Franchisee |

Assess scale of spill. Provide technical support and/or cleanup of spill |

Notify AAHK of the spill. Provide technical management of the spill and support to the AAHK Incident Coordinator including assessing whether the spill is minor or major. For major spills (spills greater than 20 litres or of a running nature), make arrangements to stop the fuel spill. Coordinate with the AAHK Incident Coordinator and provide response to contain and remove the spilt fuel. Maintain a log of events and actions taken and submit initial report to AAHK. |

|

For Other Fuel / Chemical Spills |

||

|

Tenants and Airport Operators |

Spillage containment, control and clean up of any accidental spillage of fuel or chemicals which are stored, handled and used within their premises in the airport |

Establish own response plans and procedures for dealing with fuel / chemical spills. Provide immediate action to stop, contain and remove any spilt material if it is safe to do so. Report and provide details of the incident to AAHK. Follow own spill response plans and procedures as well as the advice of the AAHK Incident Coordinator for spill response and cleanup. |

Regarding the potential for spillage of aviation fuel from storage and delivery activities, these are the responsibility of the aviation fuel supply companies and the existing established procedures shall be followed.

8.3

Types of Spills

Based on the operational phase activities associated with the 3RS project, the key types of spillages that may arise due to the project are summarised in Table 8.2.

Table 8.2: Key types of spills that may arise due to operation of 3RS project

|

|

Operational Phase |

|

|

Spill Types |

Land-based Activities |

Marine-based Activities |

|

Fuel / oil |

ü |

n/a |

|

Chemicals |

ü |

n/a |

|

Fill materials |

n/a |

n/a |

Fuels used during aircraft fuelling operation and other fuels / oils used during operation of vehicles / plants or stored onsite may be accidentally spilled due to poor handling practices, leaking fuel delivery equipment or when insufficient safeguards are provided. While such land-based spills are likely to be confined to the immediate area of the spill, the spill may seep into nearby stormwater drains and discharge into the marine environment if appropriate response actions are not taken quickly.

Chemicals used during operational phase include plant / facilities cleaning and maintenance chemicals such as lubricants and solvents. Spills are likely to be confined to the immediate area of the spill, but may seep into nearby stormwater drains and discharge into the marine environment if appropriate response actions are not taken quickly.

During the operational phase, no fill materials will be required, and there will be no marine-based activities associated with the 3RS project. Hence spillage of fill materials from marine based activities is not envisaged during the operational phase.

8.4

Spill Prevention Measures

8.4.1

Aircraft Fuelling

Spill prevention is part of the aircraft refuelling procedures prescribed in the Airport Operations Manual (AOM) issued by AAHK. Precautionary measures for aircraft fuelling operations include:

¡ An aviation fuel system emergency shutdown valve shall be available at readily accessible positions at aircraft parking stands and on all refuelling vehicles.

¡ The aircraft, refuelling vehicle, hose coupling or nozzle, filters, tunnels or any other appliance through which fuel passes, shall be effectively bonded to each other before filler caps are removed, and shall not be disconnected until the filler caps have been replaced.

¡ Cable, clips and plugs for bonding shall be kept in good condition without signs of damage or cracks.

¡ Only qualified personnel acquiring adequate training on refuelling operation shall be permitted to operate the refuelling equipment and to ensure that the fuel flow is cut off quickly in the event of emergency.

¡ For defueling operations, the amount of fuel in the bowser fuel tank should never exceed 80% of its capacity at all times. The refuelling in-charge should closely monitor the defueling quantity to ensure the volume of fuel transferred to the bowser will not exceed the 80% capacity limit.

8.4.2

Other Chemicals, Oils and Fuels

For other chemicals, oils and fuels required and used onsite, the measures specified in Section 4.3 are also relevant and shall also be applied where applicable.

8.5

Spill Response Procedures

During the operational phase, there are two distinct types of spill response procedures which will be applied depending on the types of spill, i.e. those related to aircraft fuelling activities, and those not related to aircraft fuelling activities. The spill response procedures to be effected in either case are described below.

8.5.1

Fuel Spillage from an Aircraft

Specific procedures and requirements for response to fuel spillage incident involving aircraft during servicing or manoeuvring in the airside operational area are specified as part of AAHK’s Emergency Procedures Manual. Based on the existing Manual, the following spill response procedures will be applicable:

For Minor Fuel Spillage (less than 20 litres and not of a running nature)

1. The refuelling operator must inform the Line Maintenance Franchisee and AAHK of the incident immediately, and AAHK will notify the AAHK Incident Coordinator as well as other relevant parties (such as the Airport Fire Contingent (AFC)) to arrive at the scene;

2. In parallel, immediate actions shall be taken by the refuelling operator to stop, control and contain the spilt fuel. Assistance from Line Maintenance Franchisee and AAHK should be sought if necessary with the Line Maintenance Franchisee responsible for management of the spill response including assessing if the spill is minor or major;

3. The refuelling operator shall cleanup the spilt material when it is safe to do so. Mechanical method should be used whenever possible. The Line Maintenance Franchisee and/or AAHK’s Emergency Team shall ensure all the workers involved in the cleanup works are equipped with suitable personal protective equipment (PPE);

4. Fuel should not be washed into drains or culverts. Every effort should be made to contain and recover the product;

5. If emulsifying agent is required, the emulsified contaminant must be contained and prevented from entering the storm water drainage system;

6. Contained spilt fuel and cleaning wastes / residues should be removed to a safe location for disposal. Contaminated spilt material not suitable for reuse or reprocessing shall be collected, bagged and clearly marked as “Chemical Waste, stored in a designated chemical waste area and handled and disposed of by a licensed chemical waste collector in accordance with the Waste Disposal (Chemical Waste) Regulations;

7. The refuelling operator shall maintain communication with the AAHK Incident Coordinator during the spill response, and log the event and actions taken;

8. The AAHK Incident Coordinator and AAHK’s Emergency Team shall carry out a spill investigation and complete the spill incident report with provision for recommending additional improvement and prevention measures, if applicable. The final report shall be made known to the relevant operational staff (e.g. staff responsible for spill response and clean up) and included in the future training and simulation drills and exercises if applicable.

For Major Fuel Spillage (greater than 20 litres or of a running nature)

1. The refuelling operator must inform the Line Maintenance Franchisee and AAHK of the incident immediately, and AAHK will notify the AAHK Incident Coordinator as well as other relevant parties (such as the Airport Fire Contingent (AFC)) to arrive at the scene. AAHK shall also inform Fire Service Department and the relevant Regional Office of EPD immediately;

2. In parallel, immediate actions shall be taken by the refuelling operator and/or Line Maintenance Franchisee to stop, control and contain the spilt fuel, with efforts taken to prevent spilt fuel from entering HKIA’s storm drainage system;

3. Where deemed necessary, AFC will discharge foam compound to blanket the affected area;

4. The affected area will be cleaned up by the Line Maintenance Franchisee with the assistance of the refuelling operator and/or AAHK’s Emergency Team when it is safe to do so. Mechanical method should be used whenever possible. The Line Maintenance Franchisee and/or AAHK’s Emergency Team shall ensure all the workers involved in the cleanup works are equipped with suitable personal protective equipment (PPE);

5. If emulsifying agent is required, the emulsified contaminant must be contained and prevented from entering the storm water drainage system;

6. Contained spilt fuel and cleaning wastes / residues should be removed to a safe location for disposal. Contaminated spilt material not suitable for reuse or reprocessing shall be collected, bagged and clearly marked as “Chemical Waste, stored in a designated chemical waste area and handled and disposed of by a licensed chemical waste collector in accordance with the Waste Disposal (Chemical Waste) Regulations;

7. Where required, the AAHK Incident Coordinator shall arrange with the Aviation Fuel Supply Company to deploy fuel suction machine for removal of fuel trapped in any oil interceptor chambers;

8. The Line Maintenance Franchisee shall coordinate with the AAHK Incident Coordinator during the spill response until confirmation of closeout of the incident / accident;

9. The Line Maintenance Franchisee shall prepare an initial report of the event and actions taken and submit to the AAHK Incident Coordinator. The AAHK Incident Coordinator and AAHK’s Emergency Team shall carry out a spill investigation and complete the spill incident report with provision for recommending additional improvement and prevention measures. The final report shall be made known to the relevant operational staff (e.g. staff responsible for spill response and clean up) and included in the future training and simulation drills and exercises if applicable.

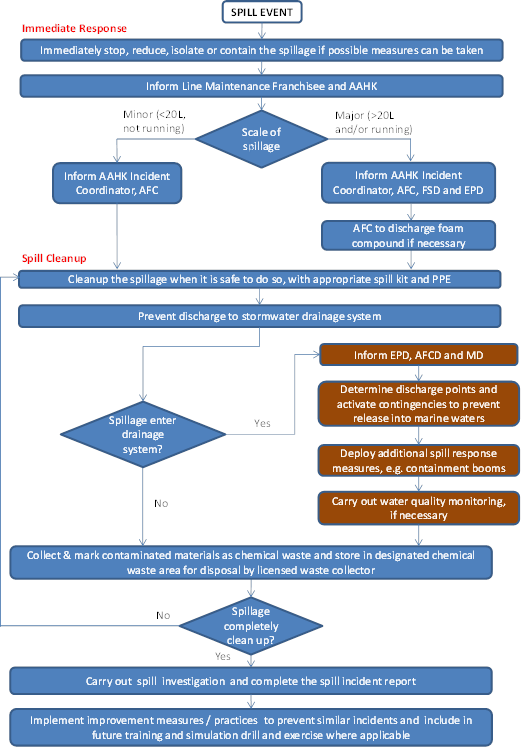

The overall process for aircraft fuel spill procedures is presented in Figure 8.1.

|

Figure 8.1: Overall Spill Response Procedure for Aircraft Fuel Spills |

|

|

8.5.2

Other Fuel / Chemical

Spills

For spillage incidents not involving aircraft servicing or manoeuvring in the airside operational area, the following spill response procedure will be applicable:

Spill Response

1. Any person discovering a fuel or chemical spillage must report it to AAHK immediately. AAHK will then initiate alerting of relevant parties. The name of the chemical and hazardous materials should be identified as far/early as possible in the emergency communication;

2. In parallel, the party responsible for the fuel / chemical spillage (i.e. AAHK for AAHK-operated facilities or the airport tenant for tenant-operated facilities) is required to effect an immediate response effort intended to stop, control and contain the spillage to prevent or minimise any safety hazard and/or contamination to the environment arising (e.g. take efforts to prevent spilt fuel / chemicals from entering HKIA’s storm drainage system) if it is safe to do so;

3. AAHK Incident Coordinator will coordinate the resources required to control and contain the fuel / chemical spillage. AAHK’s Emergency Team will also be mobilised to standby at the scene to render assistance in the control and containment of the spillage if required;

4. Once the incident is declared safe (by the Fire Services Department), the party responsible for the fuel / chemical spillage is required to physically remove the spilt material at the earliest opportunity using appropriate absorbent materials or other means. The Material Safety Data Sheet should be referred to in handling each emergency spillage incident involving chemicals;

5. Every effort should be made to retain and recover the spilt material. Contaminated spilt material not suitable for reuse or reprocessing shall be handled, stored and disposed of as chemical waste by a licensed chemical waste collector;

6. After the spilt material has been removed, the party responsible shall clean up the affected area(s) as required. Flushing of the affected area is not permitted to avoid washing the spilt material into the airport drainage system;

7. AAHK will stand by to assess for any environmental implications and to provide advice for the protection of storm drains during the cleanup of spilt material, including alerting and coordination with EPD and AFCD as required. If the spillage involves fuel or explosives, alerting and coordination with FSD would also be implemented;

8. If the spilt material enters the airport drainage system, AAHK will activate contingencies to prevent it from entering marine waters including shutting the penstocks (outfall gates) at relevant outfalls(s) if required. AAHK will also inform EPD, AFCD and Marine Department.

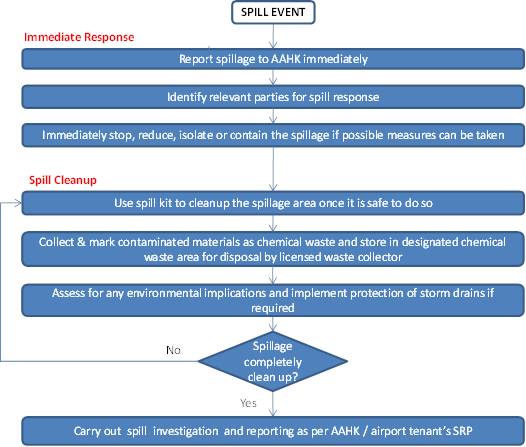

The overall process for other fuel / chemical spill procedures is presented in Figure 8.2.

|

Figure 8.2: Overall Spill Response Procedure for Other Fuel / Chemical Spills |

|

|

It should be noted that for fuel / chemical spillages within Airport tenant controlled premises (i.e. premises not operated by AAHK), the procedures for dealing with such spillages are as laid down in the tenant’s own spill response plans and procedures. However, tenants are required to report any such spillage incident / accident to AAHK and the AAHK Incident Coordinator will monitor the tenant’s response and coordinate and provide any necessary support to the tenant’s response activities as required.

8.5.3

Chinese White

Dolphins and other Marine Ecology Sensitive Receivers

In the unlikely event that a spill of oil / hazardous chemicals enters the marine environment and spreads over a large area, water quality and marine ecology sensitive receivers including Chinese White Dolphins (CWD) may be adversely affected.

To minimise the risk of adverse water quality and marine ecology impacts during operation phase, the scheme design of the 3RS has incorporated a number of prevention and protection measures, including:

¡ A ‘spill trap containment system’ at aircraft apron and stand areas;

¡ Regularly maintained oil/grease interceptors at stormwater drains;

¡ Diversion of runoff from aircraft and vehicle washing activities to foul sewer or temporary storage for subsequent removal and treatment off-site;

¡ Design of fuel pipelines and hydrant systems with adequate protection and pressure / leakage detection systems; and

¡ Restricted operation of fuel supply and refuelling systems to qualified and trained personnel with adequate knowledge of spill response procedures.

With the aforementioned measures in place, the risk of spillages entering the marine environment during the operation phase is intentionally reduced to a very low level. Nevertheless, in the unlikely event that any fuel / chemical spillages are not fully contained by the aforementioned measures and enter the stormwater drainage system leading out to sea, the following additional measures will be implemented;

1. The AAHK Incident Coordinator shall determine the discharge points of the spill based on the airport drainage plans and provide instructions to activate contingencies to prevent release into marine waters by shutting the penstocks (outfall gates) at relevant outfalls(s).

2. In parallel, AAHK will inform EPD, AFCD and Marine Department.

3. The AAHK Incident Coordinator shall ensure the appropriate spill response measures are implemented by AAHK’s Line Maintenance Franchisee / AAHK’s Emergency Team. These may include:

a. Containment booms around the affected outfalls to minimise the spread of any spill;

b. Absorption materials such as pads to cleanup the spillage as soon as possible.

4. At the advice of EPD / AFCD, water quality monitoring to detect the presence of the spilt substance(s) may be implemented by AAHK at the affected outfalls if necessary to determine any potential adverse water quality impacts to the marine environment and the need for any further mitigation measures.

5. Where necessary, AAHK shall propose and implement any further mitigation measures in consultation with EPD and AFCD.

6. AAHK shall continue to monitor the incident until the spill is completely dispersed / cleaned up and adverse impacts to the marine environment are no longer observed / detected (as confirmed by water quality monitoring results or other indicators as agreed with EPD and AFCD).

8.5.4

Neighbouring Residents

There are no neighbouring residents (i.e. non-airport operations related personnel) located within or immediately adjacent to the 3RS project area that may be affected by spillage events arising from operation of the 3RS project. Hence no specific provisions for protecting neighbouring residents are required.

8.6

Spill Control Equipment

At least one set of spill kit should be provided and stored onsite near each storage area for chemicals or chemical waste. Spill kits shall be located at designated points throughout the aircraft apron / refuelling area, and an additional set of spill kit should be located at AAHK’s Term Maintenance Contractor’s HKIA operations base. Additional spill kits shall also be provided at strategic locations where operation phase activities may create a risk of spills. AAHK / individual airport tenants shall ensure that sufficient spill kits are available at their respective premises at all times. AAHK / individual airport tenants shall ensure that relevant staff whose work involves using / handling / storing chemicals, chemical waste or fuels are aware of the locations of spill kits. The spill kit shall include, but are not limited to the following items:

¡ Oil absorbent pads;

¡ Oil absorbent socks;

¡ Sweeps;

¡ Goggles;

¡ Protective masks;

¡ Nitrile gloves;

¡ Disposal bags;

¡ Instruction sheets; and

¡ Diagram of the site / premises plan, including drainage plan covering the affected facilities.

All emergency incident handling personnel shall be familiar with the storage locations of Spill Control Equipment. Regular inspections and stocktaking of the resource materials in the spill handling should be taken at least every six months and after each spillage event by assigned qualified personnel (e.g. AAHKs’ Term Maintenance Contractor and/or individual airport tenants). Regular checking and testing of the functioning and validity date of the spill response resource materials should also be carried out at least annually by assigned qualified personnel of AAHK / respective airport tenants.

8.7

Training and Incident Recording

8.7.1

Spill Response Training

For non-aircraft related spills, appropriate training shall be provided by the individual tenants / airport operators (covering their respective premises and in accordance with their individual response plans and procedures) as part of their induction / regular training requirements.

Generally, relevant airport staff whose work involves using / handling / storing chemicals and hazardous materials / chemical wastes or fuels shall be introduced to the SRP during environmental induction trainings for such staff. During the induction trainings, a demonstration of the containment methods and equipment shall be carried out. Refresher trainings shall be conducted regularly and at least once every year. Examples of spill related training topics are shown in Table 8.3. Training records for AAHK staff and AAHK’s Term Maintenance Contractor staff shall be updated and kept in the Operational Emergency Spill Response Plan.

Table 8.3: Spill Related Training Topics

|

Training Topic |

Applicable Personnel |

|

Introduction to the SRP and its requirements on spill response |

Airport staff whose work involves using / handling / storing chemicals and hazardous materials / chemical wastes or fuels |

|

Spill prevention and detection |

As above |

|

Work safety around the spill |

As above |

|

Containment of spill |

As above |

|

Recovery and cleanup of spill |

Spill cleanup crew |

|

Handling and disposal of waste generated from spill |

Spill cleanup crew |

For spills related to aircraft operations, additional emergency response training would be conducted to ensure the refuelling crews are conversant with the contingency and spill response procedures as specified in AAHK’s Emergency Procedures Manual and in accordance with respective Franchisee spill response plans.

The following three types of spill response training are applicable:

i. New employees working on refuelling operation shall receive training on spill response and other emergency response procedures prior to commencing active duty.

ii. Simulation exercises to test the equipment, knowledge, skills and response times of refuelling personnel on spill response shall be held at least once a year.

iii. A large scale spill simulation exercise in combination with emergency services organisations and relevant Government Departments shall be held at least once every 2 years.

8.7.2

Spill Incident

Recording

For each spill incident, a record of the event and actions taken in response to the spill (including completion of appropriate action checklists based on AAHK’s Emergency Procedures Manual) shall be logged by the responsible party, and a spill incident report shall be prepared for submission to AAHK. The record / report should contain the following information:

¡ Details of the spillage incident (location, date, time, size of spill, etc.);

¡ Clean up actions taken;

¡ Findings and recommendations from follow up investigation, where applicable.

For major spill incidents that enter the marine environment, the spill investigation report shall be submitted to the Regional Office of EPD within one week. For any significant spill entering the marine environment, water monitoring results shall be provided if water quality monitoring was undertaken as part of the incident response.

Final records should be kept and maintained by the relevant responsible parties and AAHK for spillage incidences that occurred in the operating 3RS airport. Additional improvement or mitigation measures recommended by the spill investigation report should be included in the Operational Emergency Spill Response Plan.

8.8

Emergency Contacts

Table 8.4 provides the names and telephone contacts of various parties who should be contacted in case of a spill incident or emergency. As for the existing operation, it is expected that AAHK’s Airport Operation Control Centre would be the central contact point for handling emergency spillage incidents and for correspondences with relevant Government departments. The emergency contact list shall be reviewed before the 3RS operation and at least annually afterwards. Any changes should be amended and notified to all relevant parties of AAHK / airport tenants immediately, and the updated contact list should be provided to all relevant government departments within one week of amendment.

Table 8.4: Emergency Contact List (Operational Phase)

|

Role |

Contact No. |

|

AAHK Airport Operation Control Centre |

2181 8110 |

|

AAHK 24 Hours Maintenance Help Desk |

2183 6888 |

|

Airport Fire Contingent (AFC) |

2183 9447 |

|

General Emergency Services |

999 |

|

Fire Services Department |

2723 8787 |

|

Agriculture, Fisheries and Conservation Department |

2708 8885 |

|

Environmental Protection Department |

2838 3111 |

|

Fire Station |

Tung Chung Fire Station: 2988 1898 |

|

Chek Lap Kok Fire Station: 2949 9081 |

|

|

Ambulance |

Tung Chung Ambulance Depot: 2988 8282 |

|

Hospital |

North Lantau Hospital: 3467 7000 |

Individual construction Contractors are responsible for preparing their contract-specific SRP based on the general requirements specified in this Plan. Each contract-specific SRP shall be a standalone supplement to this Plan, and shall contain the following content:

Introduction / Project Description

¡ Description of the construction works under this contract / JV, including the scope, locations, types of construction activities, and programme.

¡ Potential for spills associated with this contract / JV’s works / activities.

Roles and Responsibilities

¡ Specific organisation of the emergency team for this contract / JV, including description of roles and responsibilities.

¡ Organisation chart of the emergency team for this contract / JV.

Spill Prevention Measures

¡ Specific procedures for storage, transport and use of fuels / oils, hazardous chemicals and construction materials to be implemented under this contract / JV.

¡ Specific spill prevention measures for fuels / oils, hazardous chemicals and construction materials to be implemented under this contract / JV.

Spill Response Procedures

¡ Details of the lines of spill reporting, including parties to be notified under different spill conditions and responsible parties for different actions.

¡ Details of the spill response procedures to be implemented for different types of spills under this contract / JV.

¡ Details of the specific procedures for protecting marine mammals / sensitive receivers that may be affected by this contract / JV (for spills that may enter the marine environment).

Spill Response Plan Implementation

¡ Details of the spill response training for construction workers and emergency team members / spill cleanup crew under this contract / JV.

¡ Specific types and quantities of spill response equipment available for immediate deployment in the event of a spill and their on-site storage locations for this contract / JV.

¡ Template of the spill incident investigation report

Relevant Parties Contact List

¡ Specific contacts of the project team and emergency team for the contract and any proposed variation to the relevant parties contact list of this Plan

All contract-specific SRPs shall be submitted to the AAHK and ET for review and checking to ensure the contract-specific SRP conforms to this Plan and meet the requirements of EP Condition 2.16. All contract-specific SRPs shall be certified by the ET Leader and verified by the IEC before commencement of construction of individual contracts.