|

Expansion of Hong Kong International Airport into a Three-Runway System |

|

|

Chapter Title

Appendices

Appendix A. General Structure of Contract-specific Waste Management Plan

Appendix B. Estimated Quantities of Inert C&D Material Requirements

Appendix C. Sample of CHIT, DDF and DRS

Appendix D. Sample of Summary Waste Flow Table

Tables

Figures

|

Abbreviation List

|

|

3RS |

Three-Runway System |

|

AAHK |

Airport Authority Hong Kong |

|

APM |

Automatic People Mover |

|

BHS |

Baggage Handling System |

|

C&D |

Construction and Demolition Material |

|

C&DMMP |

Construction and Demolition Material Management Plan |

|

CEDD |

Civil Engineering and Development Department |

|

CM |

Construction Manager |

|

CMP |

Contaminated Mud Pit |

|

CR |

Contractor’s Representative |

|

DASO |

Dumping at Sea Ordinance (Cap. 466) |

|

DDF |

Disposal Delivery Form |

|

DEP |

Director of Environmental Protection |

|

DRS |

Daily Record Summary |

|

EIA |

Environmental Impact Assessment |

|

EM&A |

Environmental Monitoring and Audit |

|

EO |

Environmental Officer |

|

EP |

Environmental Permit |

|

EPD |

Environmental Protection Department |

|

ES |

Environmental Supervisor |

|

ET |

Environmental Team |

|

HDD |

Horizontal Directional Drilling |

|

HKIAAA |

Hong Kong International Airport Approach Area |

|

IEC |

Independent Environmental Checker |

|

MFC |

Marine Fill Committee of CEDD |

|

MMHK |

Mott MacDonald Hong Kong Limited |

|

PET |

Polyethylene Terephthalate |

|

PFC |

Public Fill Committee of CEDD |

|

PFRF |

Public Fill Reception Facility |

|

PM |

Project Manager |

|

PPE |

Personal Protective Equipment |

|

RBRGs |

Risk Based Remediation Goals |

|

SE |

Site Engineer |

|

SQR |

Sediment Quality Report |

|

T2 |

Terminal 2 |

|

TRC |

Third Runway Concourse |

|

TCLP |

Toxicity Characteristics Leaching Procedure |

|

TTS |

Trip Ticket System |

|

UCS |

Unconfined Compressive Strength |

|

WDO |

Waste Disposal Ordinance (Cap. 354) |

|

WENT |

West New Territories Landfill |

|

WFT |

Waste Flow Table |

|

WMP |

Waste Management Plan |

|

|

|

1

Introduction

|

1.1

Background

Under the Environmental Impact Assessment Ordinance, the Environmental Impact Assessment (EIA) Report and the Environmental Monitoring and Audit (EM&A) Manual (Register No.: AEIAR-185/2014) prepared for the “Expansion of Hong Kong International Airport into a Three-Runway System” (the project) have been approved by the Environmental Protection Department (EPD), and an Environmental Permit (EP) (Permit No.: EP-489/2014) has been issued for the project. Pursuant to Condition 2.19 of the Environmental Permit (EP), the Airport Authority Hong Kong (AAHK) should prepare a Waste Management Plan for waste generated from construction activities of the project.

Mott MacDonald Hong Kong Limited (MMHK) was appointed by AAHK to provide environmental consultancy services to establish a Waste Management Plan (WMP) to be implemented for construction phase of the project. .

1.2

Project Description

This project is for expansion of the existing airport into a three-runway system with associated facilities and infrastructure. The project comprises the following key components:

¡ Construction of a third runway, related taxiway systems and navigation aids, and airfield facilities;

¡ Construction of the third runway aprons and passenger concourses;

¡ Land formation of about 650 ha to the north of the existing Airport island including a portion over the contaminated mud pits;

¡ Expansion of part of the midfield freighter apron on the existing Airport island;

¡ Expansion of the existing passenger Terminal 2 on the existing Airport island;

¡ Extension of the automated people mover from the existing Airport island to the passenger concourses of the third runway;

¡ Extension of the baggage handling system from the existing Airport island to the aprons of the third runway;

¡ Improvement of the road network in the passenger and cargo areas and new landside transportation facilities including new car parks on the existing Airport island;

¡ Reuse of treated greywater from a treatment plant;

¡ Modifications to existing marine facilities including the underwater aviation fuel pipelines and 11kV submarine cable between Hong Kong International Airport and the off-airport fuel receiving facilities, sea rescue facilities and aids to navigation; and

¡ Any other modifications, reconfiguration, and/or improvement of the existing facilities on the existing Airport island as a result of the third runway.

1.3

Purpose and Scope of the Plan

This construction WMP describes the arrangements for avoidance, minimisation, recovery, recycling, reuse, storage, collection, treatment and disposal of different categories of waste generated from the construction activities of the project, and has been prepared in accordance with Condition 2.19 of the EP:

“The Permit Holder shall no later than 3 months before the commencement of the construction of the project, deposit 3 hard copies and 1 electronic copy of a Waste Management Plan (The Plan) for the construction of the Project with the Director. The Plan shall describe the arrangements for avoidance, minimization, recovery, recycling reuse, storage, collection, treatment and disposal of different categories of waste to be generated from the construction activities and shall include the recommended mitigation measures on waste management in the approved EIA (Register No. AEIAR-185/2014).

The Permit Holder shall maximize the use of construction and demolition (C&D) materials for the land formation work during the construction phase of the Project, and shall critically review the scheduling of the surcharge operations to avoid, or otherwise, minimize generation of residual C&D materials requiring disposal during and at the end of the land formation work. The Plan shall indicate the disposal location(s) of all surplus excavated spoil and other wastes. A trip ticket system shall also be included in the plan. Surplus excavated spoil and other wastes shall only be disposed of at designated disposal locations unless otherwise approved by the Director.”

This WMP provides an overarching framework for waste management of the project, as assessed in the approved EIA Report, stated in the EM&A Manual and stipulated in the EP.

The Contractors should adopt this WMP as a basis and proforma to develop their own contract-specific WMPs. The contract-specific WMPs should be updated from time to time and submitted to the Environmental Team (ET) and Independent Environmental Checker (IEC) for their verification and AAHK for agreement. General structure for preparing a contract-specific WMP is shown in Appendix A.

The key objectives of this WMP are to:

¡ Set out the organisational structure, roles and responsibilities of key personnel responsible for the waste management and appropriate mitigation measures;

¡ Describe the arrangements for avoidance, minimization, recovery, recycling, reuse, storage, collection, treatment and disposal of different categories of waste;

¡ Include the mitigation measures on waste management as recommended in the EIA;

¡ Maximize the use of C&D materials for land formation;

¡ Review the scheduling of the surcharge operations to avoid or minimise generation of residual C&D materials requiring disposal;

¡ Identify the disposal locations of all surplus excavated spoil and other wastes; and

¡ Define the waste management procedures to be adopted throughout construction including the locations of designated disposal locations and details of the Trip Ticket System (TTS) to be implemented.

Nevertheless, the Permit Holder will strictly comply with all the waste management mitigation measures recommended in the approved EIA report, EM&A Manual, the EP, this WMP and contract-specific WMPs.

1.4

Waste Management

Legislation, Guidance and Standards

1.4.1

Statutory

Requirements

There are a number of regulations in Hong Kong which are relevant to this project as they control the storage, treatment and disposal of different waste types, including but not limited to:

¡ Waste Disposal Ordinance (Cap. 354)

¡ Waste Disposal (Chemical Waste) (General) Regulation (Cap. 354C)

¡ Waste Disposal (Charges for Disposal of Construction Waste) Regulation (Cap. 354N)

¡ Land (Miscellaneous Provisions) Ordinance (Cap. 28)

¡ Dumping at Sea Ordinance (Cap. 466)

¡ Public Cleansing and Prevention of Nuisances Regulation (Cap. 132BK)

¡ Summary Offences Ordinance (Cap. 228).

The Waste Disposal Ordinance (WDO) prohibits the unauthorised disposal of wastes, requiring disposal only at designated waste disposal facilities, licensed by the waste disposal authority.

According to the Waste Disposal (Chemical Waste) (General) Regulation, all producers of chemical waste must register with EPD and treat their wastes, either utilising on-site plant licensed by EPD, or arranging for a licensed collector to transport the wastes to a licensed facility. The Regulation also prescribes the storage facilities to be provided on site, including labelling and warning signs, and requires the preparation of written procedures and training to deal with emergencies such as spillages, leakages or accidents arising from the storage of chemical wastes.

Under the Waste Disposal (Charges for Disposal of Construction Waste) Regulation, construction waste delivered to a landfill for disposal must not contain more than 50% by weight of inert material. Construction waste delivered to a sorting facility for disposal must contain more than 50% by weight of inert material, whereas construction waste delivered to a public fill reception facility for disposal must consist entirely of inert material. Furthermore, for contracts with a value of more than HK$1M, the main Contractor is required to establish a billing account at EPD before transporting the construction waste to the designated waste disposal facilities (e.g. landfill, public fill etc.). The vessels for delivering construction waste to public fill reception facilities need prior approval from Civil Engineering and Development Department (CEDD). Breach of these regulations can lead to a fine and/or imprisonment.

The Land (Miscellaneous Provisions) Ordinance requires that dumping licenses be obtained by individuals or companies who deliver public fill to public filling areas. The CEDD issues the licences under delegated powers from the Director of Lands. The current policy related to dumping of C&D material is documented in the Works Branch Technical Circular No. 2/93 – Public Dumps. C&D materials that are wholly inert, namely public fill, should not be disposed of to landfill, but taken to fill banks or public filling areas.

The Dumping at Sea Ordinance (DASO) requires dumping permits from EPD for any marine disposal of dredged materials.

The Public Cleansing and Prevention of Nuisances Regulation provides control on illegal tipping of waste on unauthorised (unlicensed) sites.

The Summary Offences Ordinance includes provisions related to littering in the marine environment.

1.4.2

Non-statutory

Guidelines and Standards

The following guidelines and standards of practice will be adopted during construction:

¡ Waste Disposal Plan for Hong Kong (1989), Planning, Environmental and Lands Branch Government Secretariat

¡ Works Branch Technical Circular No. 02/1993, Public Dumps, Works Branch, HKSAR Government.

¡ Works Branch Technical Circular No. 02/1993B, Public Filling Facilities; Works Branch, HKSAR Government

¡ Works Branch Technical Circular No. 16/1996, Wet Soil in Public Dumps, Works Branch, HKSAR Government.

¡ Works Bureau Technical Circular No. 04/1998 and No. 04/1998A, Use of Public Fill in Reclamation and Earth Filling Projects, Works Bureau, HKSAR Government.

¡ Works Branch Technical Circular No. 19/2005, Environmental Management on Construction Site, Works Bureau, HKSAR Government.

¡ Development Bureau Technical Circular (Works) No. 6/2010, Trip-ticket System for Disposal of Construction and Demolition Material. Works Branch, Development Bureau, HKSAR Government.

¡ Works Branch Technical Circular No. 12/2000, Fill Management, Works Bureau, HKSAR Government

¡ Development Bureau Technical Circular (Works) No. 8/2010, Enhanced Specification for Site Cleanliness and Tidiness. Works Branch, Development Bureau, HKSAR Government.

¡ A Guide to the Registration of Chemical Waste Producers and Guide to the Chemical Waste Control Scheme.

¡ The Practice Notes for Authorised Persons, Registered Structural Engineers and Registered Geotechnical Engineers, PNAP ADV-21 – Management Framework for Disposal of Dredged/ Excavated Sediment (April 2007).

1.4.3

Application for Licenses, Permits and Approvals

The Contractors should apply for, where appropriate, and maintained permits and licenses required under the legislation for the handling and disposal of waste arising from the project, including but not limited to the following:

¡ Registration as a Waste Producer under the Waste Disposal (Charges for Disposal of Construction Waste) Regulation (Cap 354)

¡ Registration as a Chemical Waste Producer under the Waste Disposal (Chemical Waste) (General) Regulation (Cap. 354C)

¡ Dumping permit under the Dumping at Sea Ordinance (Cap. 466)

¡ Public Dumping License under the Land (Miscellaneous Provisions) Ordinance (Cap 28).

2

Waste

Management Hierarchy and Approach

|

2.1

Key Source of Waste Generation from the Project

The key types of waste arising during construction phase of the project identified in the scheme design and the EIA Report include C&D material, marine sediment, chemical waste, general refuse and floating refuse, which are summarised in Table 2.1. Detail of the different types of waste materials is presented in the following sections.

Table 2.1: Summary of Waste Arising During Construction Phase

|

Waste Type |

Key Sources of Waste Generation |

|

Inert C&D Material |

· Excavation works for automatic people mover (APM) & baggage handling system (BHS) tunnels, new APM depot and airside tunnels, piling works for the third runway concourse (TRC) & other buildings including superstructure construction works · Surplus surcharge material · Modification of existing northern seawall · Excavation and demolition as well as superstructure construction works for Terminal 2 (T2) expansion · Excavation for improvement of road networks · Horizontal directional drilling (HDD) for diversion of existing submarine pipelines |

|

Non-inert C&D Material |

· Site clearance of the golf course area · Demolition works for T2 expansion · Superstructure construction works for various buildings/ facilities |

|

Dredged/ Excavated Marine Sediments |

Dredging at the cable field joint area (for the diversion of the submarine 11 kV cable) |

|

Piling works of the TRC, APM & BHS tunnels, airside tunnels and other facilities on the proposed land formation area |

|

|

Piling works of marine sections of the approach lights for the third runway: · Western approach lights · Eastern Approach lights |

|

|

Piling works for the new Hong Kong International Airport Approach Area (HKIAAA) beacons |

|

|

Basement works of T2 expansion |

|

|

Excavation works of APM depot |

|

|

Chemical Waste |

Used cleansing fluids, solvents, lubricating oil, waste fuel, etc., from maintenance and servicing of construction plant and equipment |

|

General Refuse and Floating Refuse |

Food scraps, waste paper, empty containers, etc. generated from the construction workforce. Floating refuse trapped or accumulated in the newly constructed seawall. |

2.2

Hierarchy of

Waste Management

The various waste management options should be categorised in terms of preference from an environmental viewpoint. The options considered to be more preferable have the least impacts and are more sustainable in the longer term. Hence, the construction waste management strategy is illustrated as an inverted cone in Figure 2.1 which is to avoid, minimise, reuse, recycle and finally dispose of waste with the desirability descending order.

|

Figure 2.1: Inverted Cone of Construction Waste Management Strategy |

|

|

|

Source: Management Strategy for Construction Waste, EPD. http://www.epd.gov.hk/epd/misc/cdm/management_intro.htm. |

This hierarchy of waste management as shown in Table 2.2 should be used to evaluate waste management options, thus allowing maximum waste reduction. Waste reduction measures should be introduced at the planning and detailed design stage and carried through the construction activities, whenever possible, by careful purchasing control, reuse/ recycling of materials and good site management.

Table 2.2: Hierarchy of Waste Management

|

Hierarchy |

Description |

|

Avoidance and Minimisation |

Avoid and minimize generation of C&D materials and dredged/ excavated marine sediment; and trapped or accumulated floating refuse along the future artificial seawall through careful planning and design of works. |

|

Reuse |

Reuse inert portion of the C&D materials generated. Where appropriate and practicable, construction materials such as timber formwork, metal etc. should be re-used onsite. |

|

Recovery and Recycle |

Undertake on-site and off-site waste recycling. Recover and store metals, plastics, cardboard and paper packaging for subsequent collection by recycling contractors and recycling at approved disposal facilities. |

|

Treatment and Disposal |

Properly treat and dispose of waste in accordance with legislative requirements, guidelines and good practices. All chemical waste that is generated on-site will be stored for collection and disposal at approved disposal facilities. |

2.3

Waste Management

Approach to be Incorporated into this Project

The project has adopted a series of key waste management principles in the scheme design to avoid, minimise and reuse waste material generated by the project, as summarised in Table 2.3. The design consultants should adopt the hierarchy of waste management and incorporate the waste management approach as shown in Table 2.2 and Table 2.3 respectively as part of the detailed design of the project.

Details of the waste management practices for different types of waste materials are described in the following sections.

Table 2.3: Waste Management Hierarchy

|

Management Approach |

|

Waste Avoidance/ Reduction Measure |

|

Avoidance |

Land

Formation |

The use of only non-dredge methods for ground improvement will completely avoid bulk removal and disposal of any dredged materials. |

|

|

Diversion of Submarine Aviation Fuel Pipelines |

Using HDD method to construct the new pipeline will avoid dredging of the seabed, thus removal and disposal of any dredged materials will be totally avoided. |

|

Minimisation |

Diversion of Submarine 11kV Cables |

Use of water jetting method to lay the new cable will avoid generation and disposal of any marine sediment. Although it is required to dredge and dispose of about 10,200 m3 of marine sediment from the field joint area where the new cable will be connected to the existing cable, the alignment of the newly laid cable will be substantially shortened and will not need to extend to within the Sha Chau and Lung Kwu Chau Marine Park area. |

|

|

Construction

of Various Buildings and Infrastructure Facilities |

In order to minimise the extent of excavation and maximise on-site reuse of inert C&D materials generated by the project as far as practicable, relevant construction activities (particularly the tunnel works) and construction programme have been carefully planned and developed. As a result, the quantity of any surplus inert C&D materials requiring off-site delivery and the impact from the associated collection and transportation works will be minimised. |

|

Reuse |

Land Formation - Seawall Construction |

Most sloping seawall options allow for the reuse of all rock armour from the existing northern seawall to minimise waste. |

|

|

Diversion of Submarine Aviation Fuel Pipelines |

The inert C&D materials generated during the HDD work would be of a small quantity (approx. 6,000 m3), which would be fully reused in the proposed land formation. |

|

|

Land Formation - Filling Works |

Priority will be given to maximise the use of suitable fill materials available from other concurrent projects and the Government’s Public Fill Reception Facilities (PFRFs). |

|

|

Construction

of Various Buildings and Infrastructure Facilities |

All the marine sediments generated from such works will be treated and reused on-site as backfilling materials, thus avoiding the need for disposal of the sediments. |

3

Construction

and Demolition (C&D) Material

|

3.1

Inert C&D

Material

3.1.1

Estimated

Quantities and Timing for Generation

The approach used for inert C&D material management on the project is to optimise the balance of earthworks, thereby minimising the volumes of fill required to be imported to and exported from the site. Every effort would be made to minimise the extent of excavation and to ensure that as much of the inert C&D materials generated by the project as practicable will be reused on-site. For this, the relevant construction activities (particularly for the tunnel works) and construction programme have been carefully planned and developed, the tentative timing of inert C&D material generation is provided in Table 3.1, which will be subject to review and update as part of the detailed design.

Table 3.1: Estimated Annual Generation of Inert C&D Material during Construction Phase

|

Year |

Estimated Volume of Inert C&D Materials to be Generated by the Project (in-situ volume, m3) |

|

2015 |

6,000 |

|

2016 |

398,000 |

|

2017 |

710,000 |

|

2018 |

4,359,230 |

|

2019 |

1,344,270 |

|

2020 |

1,531,000 |

|

2021 |

689,000 |

|

2022 |

506,000 |

|

Total |

9,543,500 |

The combination of these initiatives is anticipated to maximise the on-site reuse of inert C&D materials as fill material for the proposed land formation as far as practicable, hence minimising the quantities of any surplus inert C&D materials requiring off-site delivery and the impact resulting from the associated collection and transportation works.

3.1.2

Maximising

On-site and Off-site Reuse of C&D Materials

On-site Reuse of Inert C&D Materials and Import of Public Fill Materials

It is estimated that the project would require a total of 14,551,000 m3 of public fill materials for the land formation work. While all practicable measures will be employed for reuse of inert C&D material generated by the project before consideration of importing material, it is anticipated in the EIA Report that approximately 3,639,230 m3 (or about 38%) of the inert C&D materials generated by the project would be reused as the fill material for land formation work, as summarised in Table 3.2, which will be subject to review and update as part of the detailed design. Further details on the breakdown of quantities are provided in Appendix B.

Table 3.2: Estimated Annual Volumes of Inert C&D Materials Required for the Land Formation Area

|

Year |

Estimated Demand of Public Fill Materials for Land Formation (in-situ volume, m3) |

Estimated Amount of Inert C&D Materials to be Reused On-site for Land Formation (in-situ volume, m3) |

Estimated Amount of Public Fill Materials to be Imported for Land Formation (in-situ volume, m3) |

|

2015* |

0 |

6,000 |

0 |

|

2016* |

1,912,000 |

398,000 |

1,508,000 |

|

2017 |

6,099,000 |

710,000 |

5,389,000 |

|

2018 |

4,788,000 |

773,230 |

4,014,770 |

|

2019 |

674,000 |

674,000 |

0 |

|

2020 |

835,000 |

835,000 |

0 |

|

2021 |

243,000 |

243,000 |

0 |

|

2022 |

0 |

0 |

0 |

|

Total |

14,551,000 |

3,639,230 |

10,911,770 |

Note: *Inert C&D materials generated from Q3 of 2015 to Q3 of 2016 would be temporarily stored in stockpiles, which would then be reused for land formation from Q3 of 2016 onwards.

Therefore, approximately 10,911,770 m3 (14,551,000 – 3,639,230 m3) of public fill materials will need to be imported to this project. Priority will be given to maximise the use of suitable fill materials available from other concurrent projects and the Government’s PFRF. AAHK will continue to liaise with the relevant concurrent projects for direct reuse of their surplus public fill for the proposed land formation works of this project.

3.1.3

Off-site Reuse

of Surplus Inert C&D Materials

It is estimated that about 5,904,270 m3 (9,543,500 – 3,639,230 m3) of inert C&D materials generated by the project could not be reused on-site, as summarised in Table 3.3, which will be subject to review and update as part of the detailed design. This volume of surplus inert C&D materials would require off-site delivery to projects requiring fill materials and/or the Government’s PFRF for beneficial use by other projects in Hong Kong.

It can be found from Appendix B that a major portion (about 3,793,000 m3) of the surplus inert C&D materials is from the surplus surcharge materials, which will be left behind after the rolling surcharge process. Therefore, scheduling of the surcharge operation and the land formation sequence/ programme will be critically reviewed by AAHK and the relevant design consultants as part of the detailed design with a view to

¡ Keeping the surplus surcharge materials to a minimum upon completion of the surcharge process; and

¡ Exploring the feasibility of reserving any suitable locations at the land formation area that can be used for filling by all or part of the surplus surcharge materials.

Table 3.3: Estimated Annual Volumes of Surplus Inert C&D Materials to be Delivered Off-site

|

Year |

Estimated Amount of Inert C&D Materials to be Generated by the Project (in-situ volume, m3) |

Estimated Amount of Inert C&D Materials to be Reused On-site for Land Formation (in-situ volume, m3) |

Estimated Amount of Surplus Inert C&D Materials to be Delivered Off-site (in-situ volume, m3) |

|

2015 |

6,000 |

6,000 |

0 |

|

2016 |

398,000 |

398,000 |

0 |

|

2017 |

710,000 |

710,000 |

0 |

|

2018 |

4, 359,230 |

773,230 |

3,586,000 |

|

2019 |

1,344,270 |

674,000 |

670,270 |

|

2020 |

1,531,000 |

835,000 |

696,000 |

|

2021 |

689,000 |

243,000 |

446,000 |

|

2022 |

506,000 |

0 |

506,000 |

|

Total |

9,543,500 |

3,639,230 |

5,904,270 |

Any surplus inert C&D materials generated from this project during the years of 2018 to 2022 should be delivered to potential projects that would require public fill. Subject to the identification of such potential projects, it is anticipated that up to about 5,904,270 m3 of inert C&D materials would be delivered to the PFRF from 2018 to 2022. Priority will be given to deliver the surplus inert C&D materials of this project to any identified projects that would require public fill during those years, and therefore delivery of the surplus inert C&D materials to the PFRF will be considered as the last resort.

Up to date, the following potential projects that may receive surplus inert C&D materials from the Three-Runway System (3RS) project have been identified:

¡ Tung Chung New Town Extension project – reclamation work scheduled to be from 2017 to 2023 according to the discussion paper from Legislative Council Panel on Development[1]

¡ Potential reclamation sites in Siu Ho Wan and Sunny Bay, the project is under planning stage and the reclamation work is tentatively scheduled to be from 2019 to 2023[2]

AAHK will continue to explore any potential projects that could receive surplus inert C&D materials.

3.1.4

Requirements for

On-Site Handling or Storage

According to the quarterly breakdown of estimated quantities inert C&D materials (Appendix B), temporary stockpiling of the inert C&D materials generated from Q3 of 2015 to Q3 of 2016 would be required in order to facilitate the subsequent reuse of such materials for the land formation work. This will be subject to review and update as part of the detailed design.

3.1.5

Disposal

Arrangement

Based on the EIA report, it is anticipated that six temporary barging points would be located around the perimeter of the newly formed land, and the construction programme of these bargaining points will be subject to the detailed design and latest overall construction programme of the project. The estimated maximum total handling capacity of inert C&D materials at the six temporary barging points will be approximately 282,000 ton/day or 141,000 m3/day (i.e. about 47,000 ton/day or 23,500 m3/day for each barging point). Barges, each with a loading capacity of about 3,000 m3, will be used for delivery of the surplus inert C&D materials that could not be reused on-site from barging points to the PFRFs designated by the Public Fill Committee (PFC) via the predefined routes as stipulated in the Marine Travel Routes and Management Plan for Construction and Associated Vessels. A TTS should be implemented for off-site delivery of such C&D materials. Details of the TTS are given in Section 3.3

A C&D Material Management Plan (C&DMMP) should be prepared as part of the detailed design, and submitted to the PFC for approval and allocation of disposal site(s). No construction work is allowed to proceed until all issues on management of C&D materials have been resolved with all relevant authorities including PFC and EPD. The C&DMMP will be updated from time to time during construction phase.

3.1.6

Recommended

Mitigation Measures

The following mitigation measures are recommended in the EIA during construction phase:

¡ Inert and non-inert C&D materials should be handled and stored separately to avoid mixing the two types of materials;

¡ Appropriate measures to minimise windblown dust during transportation of waste by either covering trucks by tarpaulin/ similar material or by transporting wastes in enclosed containers. The cover should be extended over the edges of the sides and tailboards;

¡ Stockpiles of C&D materials should be kept covered by impervious sheets to avoid wind-blown dust;

¡ All dusty materials including C&D materials should be sprayed with water immediately prior to any loading transfer operation so as to keep the dusty material wet during material handling at the barging points/ stockpile areas;

¡ C&D materials to be delivered to and from the project site by barges should be kept wet or covered to avoid wind-blown dust;

¡ To avoid or minimize dust emissions during transport of C&D materials within the site, each and every main temporary access should be paved with concrete, bituminous hardcore materials or metal plates and kept clear of dusty materials. Unpaved parts of the road should be sprayed with water or a dust suppression chemical so as to keep the entire road surface wet;

¡ The speed of the trucks including dump trucks carrying C&D materials within the site should be controlled to about 10 km/hour in order to reduce adverse dust impact and secure the safe movement around the site; and

¡ Dust control measures should be taken into account during stockpiling, loading / unloading and transportation of C&D materials.

In order to monitor the off-site delivery of surplus inert C&D materials that could not be reused on-site for the proposed land formation work to any identified potential projects that require fill materials and/or to the PFRF as well as to control fly tipping, a TTS promulgated under DEVB TC(W) No. 6/2010 should be included as one of the contractual requirements for implementation by the contractors. Details of the TTS are presented in Section 3.3.

3.2

Non-inert

C&D Material

3.2.1

Estimated

Quantities and Timing for Generation

It is estimated that approximately 8,700 m3 of non-inert C&D materials will be generated in 2017 from site clearance works at the golf course area where the new APM depot will be constructed. These non-inert C&D materials would mainly be a mixture of topsoil and vegetative materials, which are considered as unsuitable for direct reuse during any earthworks on site due to its non-inert contents, and will therefore be disposed of at designated landfill sites by a reputable licensed waste collector. The Contractors should separate such non-inert C&D materials from the inert C&D materials on-site.

Based on initial scheme design information, it is estimated that approximately 87,500 m3 of non-inert C&D materials would be generated from the demolition works for T2 expansion and various superstructure construction works from 2016 to 2021.

All the aforementioned quantities and timing of non-inert C&D materials to be generated by the project will be subject to review and update as part of the detailed design.

3.2.2

Requirements for

On-Site Handling or Storage

The non-inert C&D materials should be sorted on-site into recyclable (e.g. metal, paper, packaging and timber) and non-recyclable components (e.g. vegetation, organic material and soil), and the recyclable components should be made available for collection by recycling contractors. Different areas of the work site should be designated for such segregation and storage.

3.2.3

Disposal

Arrangement

Non-recyclable components of the non-inert C&D materials will be delivered to West New Territories (WENT) landfill by dump trucks through North Lantau Highway. A TTS should be implemented for disposal of such C&D materials. Details of the TTS are presented in Section 3.3.

3.2.4

Recommended

Mitigation Measures

The following mitigation measures are recommended in the EIA during construction phase:

¡ The Contractors should separate the non-inert C&D materials from the inert C&D materials on-site. Any recyclable materials (e.g., metal) should be segregated from the non-inert C&D materials.

¡ Use of steel or aluminium formworks and falseworks for temporary works as far as practicable;

¡ Adoption of repetitive design to allow reuse of formworks as far as practicable;

¡ Proper storage and site practices to minimise the potential for damage or contamination of construction materials;

¡ Appropriate measures to minimise windblown dust during transportation of waste by either covering trucks by tarpaulin/ similar material or by transporting wastes in enclosed containers. The cover should be extended over the edges of the sides and tailboards;

¡ C&D materials to be delivered to and from the project site by trucks should be kept wet or covered to avoid wind-blown dust;

¡ The speed of the trucks including dump trucks carrying C&D materials within the site should be controlled to about 10 km/hour in order to reduce adverse dust impact and secure the safe movement around the site; and

¡ Timber should be cleaned for reuse and timber formwork should be carefully dismantled to prevent damage. The timber should be de-nailed, cleaned and stacked neatly for re-use.

3.3

Trip Ticket System (TTS)

In accordance with TCW No. 6/2010, a TTS is implemented to track the off-site delivery or disposal of C&D materials from the site to the disposal grounds. The Contactors should prepare a Site Management Plan for implementation of the TTS. A site procedure will be developed to ensure that each truck/ barge load of C&D materials leaving the site will bear a duly completed and stamped CHIT / Disposal Delivery Form (DDF), and that the relevant waste management records have been completed and signed properly before its departure from site.

The CHIT should be used for off-site delivery of C&D material to a prescribed facility as defined under the Waste Disposal (Charges for Disposal of Construction Waste) Regulation (Cap. 354N). The DDF should be used for disposal of C&D materials at other disposal grounds as designated in the project or recycling facilities/ construction sites proposed by the Contractors and approved by AAHK / Project Manager (PM). Samples of the CHIT and DDF are shown in Appendix C. General site procedures of the TTS are provided below:

¡ Prior to the truck / barge leaving the site, the Contractors should provide a duly completed, signed and stamped CHIT / DDF to dump truck driver/ barge operator.

¡ The truck driver / barge operator should proceed to the disposal facilities as stipulated in the CHIT / DDF. The truck driver/ barge operator should present the CHIT / DDF to the reception facility operator.

¡ If the C&D materials accords with the acceptance criteria, disposal of the C&D materials will be permitted and the facility operator will give the truck driver / barge operator a transaction record slip and stamp the CHIT / DDF.

¡ For disposal at a prescribed facility, the Contractors should check the information recorded in the Daily Record Summary (DRS), as shown in Appendix C, against the disposal records from EPD’s website (http:www.epd.gov.hk/epd/misc/cdm/scheme.htm#j). The Contractors should complete Part 1 and Part 2 of the DRS form for submission to the AAHK / PM within 1 working day after the records are posted at the EPD website.

¡ For disposal ground other than prescribed facility, the Contractors should ensure that the DDF is signed off by a competent person as agreed by the AAHK / PM at the disposal ground to confirm completion of each trip. The Contractors should maintain a daily record with details of each disposal trip from the project site to the disposal ground. The Contractors should complete Part 1 and Part 2 of the DRS form for submission to the AAHK / PM within 3 working days after the date of disposal.

¡ Where an irregularity is observed or where requested by AAHK / PM under special circumstances (e.g. a CHIT / DDF has been issued but there is no disposal record at the designated disposal facilities), the Contractors should submit to AAHK / PM within 5 working days after the recorded date of disposal the supporting evidence such as duly stamped CHIT / DDF and/or the transaction record slip (where relevant) to confirm proper completion of the delivery trips in question, or within 2 working days after AAHK / PM has requested for such evidence, whichever is later. A fax copy of the CHIT / DDF or transaction record slip is acceptable, unless otherwise directed by AAHK / PM.

¡ The copies of the CHIT / DDF and the receipt should be maintained on site for future references.

Daily site inspection should be carried out by foreman, to avoid any non-compliance for TTS. No unauthorized disposal of C&D materials without the stamped DDF/ CHIT tickets will be permitted to exit and re-enter the project works area for delivery of any C&D material generated under any conditions.

The Contractors should maintain a comprehensive register filing system of the DDF/ CHIT tickets issued.

The Contractors should make the DDF register record available for inspection by AAHK / PM upon request. The Contractors should establish the record system for the recyclable materials, such as time record and delivery note number. The Contractors should also establish the TTS for chemical waste.

4.1

Estimated Quantities and Timing for Generation

A summary of the estimated volumes of marine sediments likely to be generated by the project and the proposed disposal or handling methods are summarised in Table 4.1, which is subject to review and update as part of the detailed design.

Table 4.1: Estimated Volume of Marine Sediments Generated During Construction Phase

|

Timing |

Project Component |

Estimated Total Volume (in-situ volume, m3 ) |

Disposal/ Handling Method |

|

Q3 of 2016 |

Dredging at the cable field joint area (for the diversion of the submarine 11 kV cable) |

Approx. 10,200 m3 |

Type 1 open sea disposal for Category L sediment or Type 1 open sea disposal at dedicated sites for Category Mp sediment, according to PNAP ADV-21, subject to endorsement by Marine Fill Committee (MFC) of CEDD and EPD as well as obtaining dumping permit from EPD under DASO |

|

Q4 of 2016 to Q1 of 2019 |

Basement works of T2 expansion |

About 50,730 m3 |

Treatment by cement mixing and stabilisation and on-site reuse of treated sediments as backfilling materials, although the treatment level / details and the reuse mode are under further development. |

|

Q1 of 2017 to Q3 of 2022 |

Piling works of the TRC, APM & BHS tunnels, airside tunnels and other facilities on the proposed land formation area |

Approx. 705,350 m3

|

|

|

2018 to 2019 (subject to detailed design) |

Piling works of marine sections of the approach lights for the third runway: |

Western approach lights: about 530 m3 of marine sediments Eastern approach lights: about 1,060 m3 of DCM-treated sediment |

|

|

2018 to 2019 (subject to detailed design) |

Piling works of new HKIAAA beacons |

About 220 m3

|

|

|

Q1 of 2018 to Q3 of 2020 |

Excavation works for the proposed APM depot |

About 9,770 m3 |

4.2

Requirements for On-site Treatment and Reuse

Based on the EIA report, all contaminated mud pit (CMP) and marine sediments that are excavated through the piling works required for the TRC, APM & BHS tunnels, airside tunnels and other facilities on the proposed land formation area, the piling works for marine sections of the approach lights and new HKIAAA beacons, basement works for some of T2 expansion area and excavation works for proposed APM depot (with a total quantity of about 767,660 m3) will be treated on-site using cement mixing and stabilisation/ solidification method. All these treated sediments are to be reused on-site as backfilling materials at non-critical areas (e.g., landscaping areas) of the project site, after the treated sediments have been tested to comply with the relevant standards as described below.

A minimum cement content of 5% weight per weight (w/w) is proposed as treatment of the CMP sediments and marine sediments. The treated sediment will then be tested against the relevant Risk Based Remediation Goals (RBRGs), the Toxicity Characteristics Leaching Procedure (TCLP) and the Unconfined Compressive Strength (UCS) before reuse. Subject to the TCLP and UCS test results, the cement content may need to be increased. If the treated sediments do not comply with Universal Treatment Standards (UTS) or UCS, re-stabilisation with higher cement contents has to be undertaken to meet compliance of UTS and UCS before reusing as backfilling material.

A pilot trial will be conducted for the concerned sediments (in particular the contaminated sediment excavated from within the CMP area) in order to identify/ confirm the appropriate treatment conditions for the stabilisation/ solidification methods.

The criteria for reuse of treated sediments are proposed with reference to the UTS, which specify the TCLP test limits as given in Table 4.6 of the Practice Guide for Investigation and Remediation of Contaminated Land, as shown in Table 4.2 below.

Table 4.2: Universal Treatment Standards for On-site Reuse of Sediments Treated by Cement Mixing and Stabilisation/ Solidification

|

Parameters(1),(2) |

TCLP Limit (mg/L) |

|

Arsenic |

5 |

|

Cadmium |

0.11 |

|

Chromium |

0.6 |

|

Lead |

0.75 |

|

Mercury |

0.025 |

|

Nickel |

11 |

|

Zinc |

4.3 |

Notes:

(1) Universal Treatment Standard – US 40 CFR 268.48

(2) For other metal contaminants under RBRGs, e.g., copper, silver, they must be reduced by at least 90% in mobility for respective metals through cement stabilization/solidification remedial treatment. The reduction of mobility of metal contaminants (leachable metals contaminants) should be confirmed through TCLP tests (i.e. to carry out TCLP test for the untreated sediment and for the sediment after treatment and to compare the concentrations of the metals in the leachates).

The sediment treatment facility is expected to be located within the project site depending on the construction phasing. The initially proposed treatment process is expected to begin with initial mixing of the sediments with inert C&D materials/ soil in batches using an excavator and/or backhoe. Cement slurry will then be added to the initially mixed sediment for the stabilisation/ solidification process. The treated sediments will be placed at a temporary storage area covered by tarpaulin sheets, while samples are taken for laboratory testing. The testing frequency will be one sample per 50 m3 for the first 1,000 m3 of treated sediment (two further samples should be collected at the same time and kept for contingency in case of damage to the sample being tested). Provided that the samples meet the UTS for the tested parameters shown in Table 4.2 and the UCS test, the subsequent testing frequency will be reduced to be at least two samples per 10,000 m3. In the event that required levels are not achieved, the sample should be crushed and the sediment should be treated with a higher cement content (e.g. 10%, 20% or 30%). The testing frequency should be revised to one sample per 50 m3 (with two further samples kept for contingency) and treated samples should be taken for laboratory testing. Once the UTS and UCS for the relevant tested parameters is attained, the previous sampling frequency should be resumed but the revised cement content should be maintained for treatment.

4.3

Disposal

Arrangement

The marine sediments to be dredged from the cable field joint area (with a quantity of about 10,200 m3) would need to be disposed off-site due to non-alignment with the overall construction programme as per the EIA. The exact arrangement and quantity of dredged sediments requiring disposal will be reviewed as part of the detailed design work.

Should it be confirmed necessary to dispose of the marine sediments from the cable field joint area after the review, a DASO permit from the Director of Environmental Protection (DEP) is required for the disposal of marine sediment. At least three months prior to commencement of the dredging work at the field joint area, the Contractor should submit a Sediment Quality Report (SQR) in accordance with PNAP ADV-21 in order to apply for a dumping permit from EPD for marine disposal of the sediments under the provisions of DASO. The actual amount of sediment and the allocation of disposal site(s) will be determined based on the results of the SQR to be approved by EPD and MFC.

No field joint dredging work is allowed to proceed until all matters on management of dredged sediments have been resolved and all relevant arrangements have been endorsed by the relevant authorities including EPD and MFC.

The SQR should include the following:

¡ Sampling details;

¡ Chemical testing results;

¡ Quality control records;

¡ Proposed classification and delineation of sediment in accordance with PNAP ADV-21; and

¡ Information and / or records as specified by DEP in his approval of sediment sampling and testing plan.

During disposal, the marine sediments should be loaded onto barges, transported to and disposed of at the designated disposal sites to be allocated by the MFC depending on their level of contamination or at other disposal sites after consultation with the MFC and EPD.

Based on the EIA Report, the relevant chemical and biological testing results of the sediment samples, the marine sediment to be dredged from the field joint area is classified as Category L or Category Mp and would be disposed by Type 1 open sea disposal (for Category L sediment) or Type 1 open sea disposal at dedicated sites (for Category Mp sediment) respectively, according to PNAP ADV-21.

4.4

Recommended Mitigation Measures

4.4.1

Excavation and

Treatment of Sediment

The following mitigation measures are recommended in the EIA during excavation and treatment of the sediments:

¡ On-site treatment should be carried out in an enclosed area in order to minimise odour/ dust emissions;

¡ The loading, unloading, handling, transfer or storage of treated and untreated sediment should be carried out in such a manner to prevent or minimise dust emissions;

¡ All practical measures, including but not limited to speed control for vehicles, should be taken to minimise dust emission;

¡ Good housekeeping should be maintained at all times at the sediment treatment facility and storage area;

¡ Treated and untreated sediment should be clearly separated and stored separately; and

¡ Surface runoff from the enclosed area should be properly collected and stored separately, and then properly treated to levels in compliance with the relevant effluent standards as required by the Water Pollution Control Ordinance before final discharge.

4.4.2

Disposal of

Sediment

For disposal of the marine sediments to be dredged from the cable field joint area (if found to be necessary), the contaminated sediments should be dredged and transported with great care, and the following mitigation measures as recommended in the EIA should be strictly followed to minimise impact on water quality during transportation of the sediments requiring Type 1 disposal:

¡ Bottom opening of barges should be fitted with tight fitting seals to prevent leakage of material;

¡ Silt curtains surrounding the closed grab dredger should be deployed as a precautionary measure;

¡ Monitoring of the barge loading should be conducted to ensure that loss of material does not take place during transportation. Transport barges or vessels should be equipped with automatic self-monitoring devices as specified by EPD;

¡ Barges or hopper barges should not be filled to a level that would cause the overflow of materials or sediment laden water during loading or transportation; and

¡ Excess materials should be cleaned from the decks and exposed fittings of barges and hopper dredgers before the vessels are moved.

5

Chemical

Waste

|

5.1

Timing for generation

The generation of chemical wastes from the maintenance of plant and servicing of construction plant and equipment is anticipated throughout the construction phase of the project and will be dependent on the utilisation of plant and equipment. The quantity of chemical waste that will be generated is anticipated to be in the order of a few thousand litres per month. Estimation of the generation quantity of chemical waste is to be provided by the contractors in their contract-specific WMPs. All the contractors will be required to register with the EPD as chemical waste producers.

5.2

Requirements for On-site Handling and Storage

Chemical waste should be handled in accordance with the Code of Practice on the Packaging, Handling and Storage of Chemical Waste. The details are described as follows:

Containers used for the storage of chemical waste should:

¡ Be suitable for the substance they are holding, resistant to corrosion, maintained in a good condition, and securely closed;

¡ Have a capacity of less than 450 litres unless the specification have been approved by EPD; and

¡ Display a label in English and Chinese in accordance with instruction prescribed in Schedule 2 of the Regulations.

The storage area for chemical waste should:

¡ Be clearly labelled and used solely for the storage of chemical waste;

¡ Be enclosed on at least three sides;

¡ Have an impermeable floor and bund, 110% capacity of the largest container or 20% of the storage capacity, whichever is the greatest;

¡ Have adequate ventilation;

¡ Be covered to prevent rainfall entering (water collected within the bund must be tested and disposed as chemical waste if necessary); and

¡ Be arranged so that incompatible materials are adequately separated.

5.3

Disposal Arrangement

Materials classified as chemical wastes will require special handling and storage arrangements before off-site disposal at Chemical Waste Treatment Centre or other licensed chemical waste recycling/ treatment facilities. The chemical wastes will be delivered to the off-site licensed facilities by trucks through North Lantau Highway and Tsing Sha Highway.

5.4

Recommended Mitigation Measures

All the contractors will be required to follow the guidelines stated in the “Code of Practice on the Packaging Labelling and Storage of Chemical Wastes”.

Preventive measures should be implemented for leakage and spillage of fuel and lubricating oil to avoid contamination of the construction site. All on-site equipment maintenance workshops should be located on impermeable areas with provision of drainage channels and interceptors to allow separation of oils from water and release of treated water. All plant and equipment should require regular maintenance. The maintenance records should be kept in site office for future reference.

Good housekeeping practices should be adopted to deal with chemical waste include:

¡ Generate less chemical waste through:

– Delivering appropriate quantity of chemicals to the construction site.

– Avoiding unnecessary wastage of chemicals by using the chemicals more sensible and in accordance with the manufacturer’s instructions.

– Finishing one bottle/container of chemicals before opening the next one for use.

– Collecting the remaining chemicals in suitable containers.

– Removing the unused chemicals out of the construction site after completion of the project.

¡ Prevent illegal discharge of chemicals or chemical wastes.

¡ Minimise the volume of unused chemicals to be disposed of through:

– Using the chemicals before the expiry date.

– Ordering appropriate quantity of chemicals and avoiding unnecessary storage of excess chemicals.

6

General

Refuse

|

6.1

Estimated Quantities and Timing for Generation

In the EIA Report, it is estimated that the maximum daily arising of general refuse from construction workers would be up to 9,100 kg based on a generation rate of 0.65 kg per worker per day and the tentatively anticipated maximum number of on-site workers of up to 14,000. Estimation of the amount of general refuse to be generated should be provided by the contractors in their contract-specific WMPs.

6.2

Requirements for On-Site Handling or Storage

The general refuse should be temporarily stored in enclosed bin to avoid adverse impact to the surroundings. Recycling bins should be provided to maximise waste reuse and recycle volume. Waste storage areas should be well maintained and cleaned regularly to avoid attracting pests and vermin.

6.3

Disposal Arrangement

General refuse will be disposed of at WENT landfill. A reputable waste collector should be employed by the Contractors to remove general refuse, separately from C&D material and chemical wastes. General waste will be collected regularly to minimise odour, pest and litter impacts. The burning of refuse on construction sites (which is prohibited by law) or disposal at sites other than the approved waste transfer or disposal facilities should be prohibited.

6.4

Recommended Mitigation Measures

Release of any general refuse into marine waters should be strictly prohibited. General refuse should be stored in enclosed bins or compaction units separated from inert C&D material. Preferably an enclosed and covered area should be provided to reduce the occurrence of 'wind blown' light material.

Site office management will promote environmental awareness and waste reduction by reducing the amount of paper generated (such as double-sided copying and reuse of waste paper). Collection of recyclable materials such as aluminium cans, Polyethylene Terephthalate (PET) bottles and paper should be encouraged by providing separate labelled bins to enable these wastes to be segregated from other general refuse generated by the work force.

7

Floating

Refuse

|

7.1

Estimated Quantities and Timing for Generation

Based on the EIA Report, it is estimated that roughly 65 m3 of floating refuse will be collected from the newly constructed seawall each year during the construction period. This will be subject to review and update by the relevant design consultant/ contractors.

7.2

Requirements for On-Site Handling or Storage

The floating refuse should be temporarily stored in enclosed bin to avoid adverse impact to the surroundings. Waste storage areas should be well maintained and cleaned regularly to avoid attracting pests and vermin.

7.3

Disposal Arrangement

Floating refuse will be collected by a reputable licensed waste collector for disposal at WENT landfill by dump trucks through North Lantau Highway.

7.4

Recommended

Mitigation Measures

The future artificial seawall of the proposed airport expansion area should be properly designed to achieve a shoreline that does not have any sharp turns or abrupt indentation in order to avoid or minimise any trapped or accumulated refuse. The Contractors will be required to regularly check and clean any refuse trapped or accumulated along the newly constructed seawall.

8

Organisation

Structure for Waste Management

|

8.1

Overall Organisation Structure

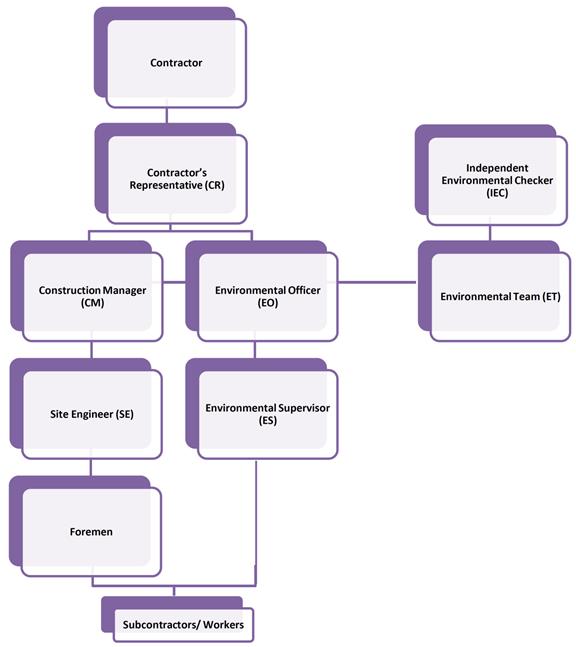

AAHK or its appointed Project Manager (PM), together with the IEC and the ET will be responsible for overseeing and ensuring the WMP is effectively implemented by the Contractors during their relevant construction works. Details of the roles and responsibilities of key personnel are presented below and the organisation structure is shown in Figure 8.1.

8.1.1

Airport

Authority Hong Kong (AAHK) / Project Manager (PM)

AAHK is the project proponent for the development of the project, and has overall responsibility for the project. The main responsibility of the AAHK / PM is to oversee and manage the Contractors’ implementation of the WMP.

8.1.2

Environmental

Team (ET)

The ET will be employed by AAHK and should not be in any way an associated body of the Contractors or the IEC. The ET is responsible to:

¡ Maintain overall control of the monitoring and professional services required under the conditions of the EP, the EIA Report and the EM&A Manual;

¡ Prepare and update the WMP with assistance from the Contractors;

¡ Investigate and inspect the Contractors’ equipment and work methodologies with respect to waste management and associated mitigation measures;

¡ Review the programme of works to anticipate any potential waste management implications;

¡ Liaise with the IEC on the waste management matters;

¡ Audit and report the implementation status of waste management mitigation measures from site inspections;

¡ Provide advice to the Contractors on waste management improvement, awareness and enhancement matters on-site;

¡ Investigate any environmental complaints, including those on waste management matters;

¡ Carry out weekly waste management audits.

8.1.3

Independent

Environmental Checker (IEC)

The IEC will be employed by AAHK and should not be in any way an associated body of the Contractors and the ET. The IEC is responsible to:

¡ Undertake the duties defined in the EM&A Manual and the EP, audit the overall EM&A programme described in the EIA Report and the EP, including the implementation of all environmental mitigation measures, submissions required in the EM&A Manual and the EP;

¡ Verify the WMP and any subsequent updates on WMP;

¡ Verify the environmental acceptability of Contractors’ works with respect to waste management and environmental mitigation measures;

¡ Liaise with the ET on all the waste management matters;

¡ Verify the investigation result of any environmental complaints, including those on waste management matters; and

¡ Carry out at least monthly waste management audits and recommend any changes as appropriate.

|

|

|

Note: * The ET and IEC are responsible for maintaining overall monitoring and checking of implementation of WMP by each Contractor. |

8.2

Organisational Structure of Individual Contractor

Each Contractor is responsible for the implementation of WMP within the scope of their relevant construction works. The organisation structure of individual Contractor is shown in Figure 8.2. The Contractor is also responsible for ensuring commitment and sufficient resources to provide an effective environmental management program, which includes waste management, for all the construction works.

The details of the roles and responsibilities of key site personnel of the individual Contractor are described below. Upon appointment, each Contractor may refine the roles in accordance with the company’s management structure and assign suitable members of staff.

8.2.1

Contractor’s

Design Engineers

The design engineer is responsible for setting requirements on waste minimisation during planning process, including setting up procedures and commitments for reducing waste on-site. Waste minimisation decisions should be recorded within the contract-specific WMPs. Decisions may be related to the nature of the project, design, construction method or material selection.

8.2.2

Contractor’s

Representative (CR)

The Contractor’s Representative (CR) is responsible for ensuring the implementation of WMP and assigning the necessary resources to ensure its effective implementation. The responsibilities of the CR include, but are not limited to:

¡ Overview of day-to-day site practices in relation to waste management;

¡ Direct Construction Manager (CM), Site Engineer (SE) and Foremen as appropriate in supervising and enforcing the on-site mitigation measures; and

¡ Ensure compliance of all relevant waste management legislations during construction.

8.2.3

Construction

Manager (CM)

The Construction Manager (CM) reports to the CR, the responsibilities of the CM include, but are not limited to:

¡ Coordinate all environmental matters related to the WMP;

¡ Be responsible for all site operations, management of environmental issues, staff supervision, control, coordination and planning, external liaison as well as implementing and monitoring corrective actions related to the WMP;

¡ Ensure all required licences and permits required for the construction phase are applied for and are valid throughout the duration of the period for which they are required, such as the DASO permit and Public Dumping Licence;

¡ Carry out immediate corrective action to rectify any non-compliance of environmental requirements of the WMP. when necessary, as well as handle any complaints that are received from the public regarding the WMP;

¡ Oversee the implementation and performance of the WMP; and

¡ Assist with environmental duties on-site and ensure that works are executed in accordance with the WMP, as well as arranging regular site inspections with the Environmental Office (EO).

8.2.4

Environmental

Officer (EO)

The EO will be appointed on-site for the overall coordination, monitoring, oversight and implementation of the WMP. The EO directly reports to the CR. The responsibilities of the EO include, but are not limited to:

¡ Review of the WMP for implementation of the TTS and ensure works are executed in accordance with the plan;

¡ Monitor on-site work to ensure compliance with the environmental requirements for the site;

¡ Carry out inspections of the site to identify potential hazards to the environment, reporting findings with recommendations for corrective actions;

¡ Complete and submit the Monthly Summary Waste Flow Table (WFT) and Yearly Summary WFT;

¡ Assist the CM in handling any complaints that are received;

¡ Ensure that the required environmental monitoring is carried out, and that all environmental monitoring results are recorded; and

¡ Carry out waste management training/ tool-box talks for all site staff and subcontractors.

8.2.5

Site Engineer

(SE)

The Site Engineer (SE) is responsible to:

¡ Coordinate with the EO regarding the implementation of all appropriate environmental mitigation measures; and

¡ Coordinate with the EO to ensure that all the applicable environmental licenses and permits are identified and allowed for in the programme of work.

8.2.6

Environmental

Supervisor (ES)

The Environmental Supervisor (ES) is responsible for the implementation of the WMP with the assistance of the Foremen. The ES is also responsible for:

¡ Co-operate with the EO to rectify any non-conformities with the environmental requirements of this WMP that are identified on-site;

¡ Attend environmental meetings related to waste management when necessary;

¡ Carry out environmental site inspections with the EO when deficiencies in waste management are identified;

¡ Assist the EO with any environmental accidents, such as the release of chemicals; and

¡ Assist the EO with waste management training/ tool-box talks for all site staff and subcontractors

8.2.7

Foremen

The foremen are responsible for on-site supervision, the coordination of the works as well as the implementation of any corrective actions as directed by the CM/ EO. The foremen are also responsible for:

¡ Assist in the daily implementation of the WMP including the sorting and segregation of construction waste into separate stockpiles and where possible recycling (via recycling containers) or reusing materials;

¡ Ensure the TTS is followed and that all appropriate paperwork are signed, completed and collected;

¡ Supervise and monitor the works of subcontractors/ construction workers in relation to waste management;

¡ Ensure waste is avoided and/or minimised as much as practically possible; and

¡ Report non-compliance of environmental protection, including waste management issues

8.2.8

Subcontractors /

Construction Workers

Subcontractors and their employees have a duty to carry out agreed waste management practices as instructed by the CR. Every employee should report promptly to management on any non-compliance related to waste management and the TTS. All subcontractors and construction workers must comply with the waste policy of the Contractors and the TTS. They should attend waste management training organised by the EO.

|

Figure 8.2: Waste Management Organisation Structure of Individual Contractor |

|

|

9

Waste

Management Records and Training

|

9.1

On-site Record of Waste

9.1.1

Waste Flow Table

(WFT)

The Contractors should establish a mechanism to record all the waste generated each month, using the Monthly Summary WFT. A sample of Monthly Summary WFT is provided in Appendix D. The Contractors should record actual quantities of wastes generated in each month in the Monthly Summary WFT and submit it to AAHK / PM.

The estimated and actual quantities of wastes that will be generated each year from the project will be reported, using the Yearly Summary WFT, which is attached in Appendix D.

9.1.2

Waste Management

Records

In addition to the CHIT and DDF records required to be retained by the Contractors, a system should be in place to record the quantities of surplus materials and wastes generated each month. These records would include, but not limited to, the following:

¡ Relevant licences and permits, including dumping permits and registration as chemical waste producer;

¡ Records of quantities of waste generated, recycled and disposed (including the disposal sites);

¡ Trip tickets for C&D material and chemical waste disposal; and

¡ Any waste management training record.

The above records of each calendar month should be submitted to the SE and AAHK / PM within the first week of the following calendar month.

In addition, where it is necessary to use timber for temporary works construction, the Contractors should provide a summary table, as attached in Appendix E, containing the description, justification and the estimated quantity for every work process / activity requiring the use of timbers for temporary works irrespective of the quantity of timber used. The summary table should be submitted to AAHK / PM with the WFT.

After the completion of the project, the Contractors should submit a report on the implementation of the WMP with the content to be agreed by AAHK / PM. The report should include the following information and any other information as the AAHK / PM may consider appropriate:

(a) The quantities of different types of C&D material as estimated at the commencement of the project;

(b) A statistics on the monthly quantities of different types of C&D material generated and their disposal method; and

(c) Reasons for any significant differences between the estimated quantities in (a) and the actual quantities in (b).

9.2

Site Staff Training

The Contractors will ensure that all site staff members attend an environmental management training course. The training will cover the surplus material management policy, targets, measures for waste reduction, reuse & recycling, on-site sorting of C&D materials and performance measurement on the site.

The content of the training will include the following:

¡ Concepts of Site cleanliness.

¡ The steps / requirements of the WMP stipulated in the project.

¡ Classification of different waste types in accordance with the WMP.

¡ Proper segregation, handling and storage of different types of waste in accordance with the WMP.

¡ Procedures and measures for waste minimisation, reuse and recycling.

¡ Locations of designated storage areas for different waste types in accordance with the WMP.

¡ Handling of contaminated material, including the appropriate Personal Protective Equipment (PPE) requirements.

¡ Procedures for handling contaminated material.

¡ Emergency Response Procedure and mitigation measures.

Furthermore the CR will assign a member of staff, such as the EO or ES, to provide additional on-site training regarding site cleanliness and waste management procedures on a monthly basis to review relevant statutory regulations and waste management practice and to discuss relevant contract requirements. This training should be provided to all levels of staff as well as subcontractors.

All foremen and subcontractors’ representatives should be trained regarding the presentation of the tool-box talks by the EO. Training material for tool-box talks should be prepared by the EO and disseminated to all workers by foremen and subcontractor’s representatives at regular intervals as a means to promote environmental awareness and provide updated issues regarding waste management practices.

An auditable record will be maintained for all environmental training undertaken.

10 Waste Monitoring and Audit

|

The Contractors are responsible for all waste management activities under their works contracts during the construction phase. The Contractors must ensure that all wastes produced during the construction phase are handled, stored and disposed of in accordance with EPD’s regulations and requirements and in line with good waste management practices.

The Contractors should perform regular site inspection (at least once per week) to determine if wastes are being managed in accordance with approved procedures. Waste materials generated during the construction works, such as inert C&D material, general refuse and chemical wastes, are recommended to be monitored on a weekly basis to ensure that proper storage, transportation, reuse, recycling and disposal practices are being implemented. This monitoring of waste management practices will ensure that these solid and liquid wastes are not disposed into the nearby waters. The Contractors should be responsible for the implementation of any mitigation measures to minimise waste or redress problems arising from the waste materials.

In addition, the ET will carry out weekly site inspections in accordance with the EM&A Manual approved under the EIA Ordinance. The ET will identify any non-compliance with the EM&A Manual and the contract-specific WMPs, and will report them accordingly. The results of the waste management audits would be reported in the monthly EM&A reports.

[1] Tung Chung New Town Extension Study Stage Three Public Engagement, Draft Recommended Outline Development Plan, Legislative Council Panel on Development, 28 October 2014.

[2] Enhancing Land Supply Strategy: Reclamation Outside Victoria Harbour and Rock Cavern Development, Advisory Council on the Environment, 9 March 2015.