|

Expansion of Hong Kong International Airport into a Three-Runway System |

Contents

1

Introduction

1.1

Purpose

of the Manual

1.1.1.1 In accordance with Condition

3.1 of Environmental Permit (EP) (EP No. EP-489/2014), an updated Environmental

Monitoring and Audit (EM&A) Manual shall be prepared before the

commencement of construction works. The first submission of Updated EM&A

was made to the Environmental Protection Department (EPD) on 18 September 2015,

and finalised and release via the project’s dedicated website in January 2016.

1.1.1.2

The purpose of this updated EM&A

Manual (hereafter referred to as the Manual) is to guide the setup of an

EM&A programme to ensure compliance with the recommendations in the

approved Environmental Impact Assessment (EIA) Report (Register No.

AEIAR-185/2014), to assess the effectiveness of the recommended mitigation

measures and to identify any further need for additional mitigation measures or

remedial action. This Manual outlines the monitoring and audit programme

proposed for the “Expansion of Hong Kong International Airport into a

Three-Runway System” (the project).

1.1.1.3

In this updated submission, Section 5

incorporates revised sensitive receiver water quality monitoring locations.

Section 10 incorporates an alternative method for passive acoustic monitoring

of Chinese White Dolphin and the alternative approach for undertaking Dolphin

Exclusion Zone Monitoring.

1.2

Project Description

1.2.1.1

The project will consist of a new third runway with associated taxiways,

aprons (or aircraft stands), as well as new passenger concourse buildings and

expansion of the existing Terminal 2 (T2) building. Included in the project

will be related airside and landside works and associated ancillary and

supporting facilities.

1.2.2

Land

Formation

1.2.2.1

Based on the preferred airport development option identified, land is

required to be formed to the north of the existing airport island, which will

provide a platform for the development. The proposed land formation works will

mainly include:

● Land formation of not more than 650 ha

to the north of the existing airport island with partial construction over the

contaminated mud pits. The area of land formation is defined to be the area at

and above the high water mark of +2.3 mPD; and

● Modification and integration of the

existing seawall at the northern, western and eastern sides of the existing

North Runway into the new land formation and re-provisioning of new seawall

around the land formation.

1.2.3

Airfield

Facilities

1.2.3.1

The proposed airfield facilities will mainly include:

● Construction of a third runway,

related taxiway systems, associated airfield infrastructure, aircraft

navigational aids, approach lighting systems and new Hong Kong International

Airport Approach Area (HKIAAA) beacons;

● Construction of the third runway

passenger concourse (TRC) aprons;

● Temporary closure and modification

of the existing North Runway along with related taxiway systems; and

● Expansion of the freighter aprons in

the existing Midfield area between the existing North and South runways.

1.2.4

Passenger

Facilities

1.2.4.1

The proposed passenger facilities will mainly include:

● Construction of the TRC and

passenger fixed link bridges;

● Expansion of the existing passenger

T2;

● Extension of the automated people

mover (APM) and associated depot and maintenance / stabling areas; and

● Expansion of the baggage handling

system (BHS) and associated baggage halls and early bag store.

1.2.5

Ancillary

Facilities

1.2.5.1

New ancillary facilities will be provided to support the operational

needs of the TRC and airfield facilities. These ancillary facilities will be

located on the west and east sides of the proposed land formation area (i.e. within the western support area and the eastern

support area respectively) and will accommodate utility buildings, airport

support developments, air cargo staging, catering, aircraft maintenance,

aircraft engine run-up (engine testing) facilities, ground services equipment

area, early bag storage facility, fire station, fire training facility, petrol

fuelling station, new air traffic control towers (ATCTs), Hong Kong Observatory

(HKO) facility, mobile phone system antenna towers, stores, security gate houses,

etc.

1.2.6

Infrastructure

and Utilities

1.2.6.1

The proposed infrastructure and utilities will mainly include:

● Expansion of the landside and

airside road network in the passenger, cargo and maintenance areas and landside

transportation facilities, including new car parks;

● Construction of new airside road

access, including the construction of new airside road tunnels and ramps, to

connect the new third runway facilities with the existing airport;

● Modification to existing and

construction of new land based infrastructure including the seawater cooling

and flushing system, stormwater drainage system, greywater system, sewerage

network and potable water supply, Towngas supply,

132 kV / 11 kV and other power supply networks; communication networks; and

● Modifications and re-provisions to

existing marine facilities including the underwater aviation fuel pipelines

between Hong Kong International Airport (HKIA) and the off-airport fuel

receiving facilities at Sha Chau, the associated underwater 11 kV cable and

pilot cable and sea rescue boat points.

1.2.6.2

The key project components are shown in Drawing No. MCL/P132/EMA/1-001 to MCL/P132/EMA/1-004.

1.3

Tentative

Construction Programme

1.3.1.1

The tentative programme for operation of the three-runway system (3RS)

will be in 2024. Given the scale and complexity of the project, construction

and the concurrent runway operational configuration will be implemented in

phases. The tentative phasing programme is provided in Appendix

A which is based on the currently

available information. This programme is subject to change during the detailed

design stage.

1.4

Project

Organisation

1.4.1.1

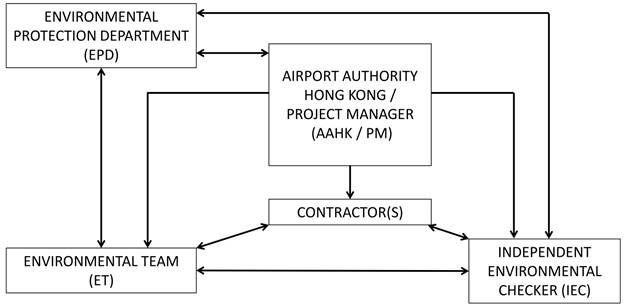

The proposed project organisation is shown in Chart 1-1 below.

|

|

1.4.2

Airport Authority Hong Kong (AAHK)

1.4.2.1

AAHK is the project proponent for the development of the project and

will assume overall responsibility for the project.

1.4.3

Environmental

Protection Department (EPD)

1.4.3.1

EPD is the statutory enforcement body for environmental protection

matters in Hong Kong.

1.4.4

Project

Manager (PM)

1.4.4.1

The Project Manager (PM) or the PM’s

Representative is responsible for overseeing the construction works and for ensuring

that the works are undertaken by the Contractor in accordance with the

specification and contract requirements. The duties and responsibilities of the

PM with respect to EM&A include:

● To monitor the Contractor’s

compliance with Contract Specifications, including the effective implementation

and operation of the environmental mitigation measures;

● To employ an Independent

Environmental Checker (IEC) to audit the results of the EM&A works carried

out by the Environmental Team (ET);

● To monitor Contractors’ compliance

with the requirements in the EP and updated EM&A Manual;

● To facilitate ET’s implementation of

the EM&A programme;

● To participate in joint site

inspection by the ET and IEC;

● To oversee the implementation of the

agreed Event and Action Plan in the event of any exceedance; and

● To adhere to the procedures for

carrying out complaint investigation.

1.4.5

Contractors

1.4.5.1 The Contractors

employed by AAHK, including Contractors working on the project on a joint

venture (JV) basis, should report to the PM or the PM’s Representative. The

duties and responsibilities of the Contractors include:

● To comply with the relevant contract

conditions and specifications on environmental protection;

● To facilitate ET’s monitoring and

site inspection activities;

● To participate in the site

inspections undertake by the ET and IEC, and undertake any corrective actions;

● To provide information / advice to

the ET regarding works programme and activities which may contribute to the

generation of adverse environmental impacts;

● To submit proposals on mitigation

measures in case of exceedance of Action and Limit Levels in accordance with

the Event and Action Plans;

● To implement measures to reduce

impact where Action and Limit Levels are exceeded; and

● To adhere to the complaint handling

procedures in accordance with this Manual and the Complaint Management Plan.

1.4.6

Environmental

Team (ET)

1.4.6.1

A full time on-site ET should be employed by the AAHK / PM to conduct

the EM&A programme no later than one month before the commencement of

construction of the project. The ET should not be in any way an associated body

of the Contractor or the IEC for the project. The ET should be headed by the

full time on-site ET Leader (ETL). The ETL should have relevant professional

qualifications in environmental control and possess at least seven years of

experience in EM&A or environmental management. Suitably qualified staff

should be included in the ET, and resources for the implementation of the

EM&A programme should be allocated to enable fulfilment of the project’s

EM&A requirements during construction of the project. The ET should report

to AAHK / PM and the duties should include:

● To carry out field sampling, field

measurement, testing, assessment, and reporting for various environmental

parameters as required in this EM&A Manual;

● To analyse the EM&A data, review

the success of EM&A programme and the adequacy of mitigation measures

implemented, confirm the validity of the EIA predictions and identify any

adverse environmental impacts arising and recommend suitable mitigation measures;

● To monitor compliance with

conditions in the EP, environmental protection, pollution prevention and

control regulations and contract specifications;

● To carry out regular site inspection

at least once per week so as to investigate and audit Contractor’s site

practice, equipment and work methodologies with respect to pollution control

and environmental mitigation;

● To report on the EM&A results to

the AAHK / PM, IEC, EPD and Contractors;

● To vet the Contractor’s method

statements, design plans and submissions and check that the relevant

environmental protection and pollution control measures have been included and

are sufficient to comply with contractual and statutory requirements;

● To inform the AAHK / PM, IEC and

Contractors the recommend suitable mitigation measures in the case of

exceedance of Action and Limit Levels in accordance with the Event and Action

Plans;

● To liaise with the IEC on all environmental

performance matters, and ensure timely submission of all relevant EM&A pro

forma for IEC’s approval;

● To provide advice to the Contractors

on environmental improvement, awareness and enhancement matters, etc. on site;

● To prepare, certify and submit the

Baseline, Monthly, Quarterly, Annual and Final EM&A Review Reports to the

AAHK / PM, IEC and EPD timely;

● To keep a contemporaneous log-book

of each and every instance or circumstance or change of circumstances, which

may affect the compliance with the recommendations of the approved EIA Report

and the EP; and

● To set up and manage the dedicated

complaint hotline and email channel, and manage the complaint handling

procedures in accordance with this Manual and the Complaint Management Plan.

1.4.7

Independent Environmental Checker (IEC)

1.4.7.1

The IEC is empowered to audit the environmental performance of

construction, but is independent from the management of construction works. As

such, the IEC should not be in any way an associated body of the Contractor or

the ET for the project. A full time on-site IEC with a supporting team should

be employed by the AAHK / PM no later than one month prior to the commencement

of the construction of the project. The IEC should be a person who has relevant

professional qualifications in environmental control and at least seven years

of experience in EM&A or environmental management. The duties and

responsibilities of the IEC are:

● To provide proactive advice to the

AAHK / PM on EM&A matters related to the project;

● To verify the environmental

acceptability of permanent and temporary works and relevant design plans;

● To review and verify the monitoring

data and all submissions in connection with the EP, any subsequent Variations of EP (VEPs) and / or

Further EP (FEPs), and

EM&A reports submitted by the ET;

● To arrange and conduct at least

monthly site inspections of the works during the construction phase, and to

carry out ad hoc inspections if significant environmental problems are

identified;

● To validate and check the accuracy

of environmental monitoring;

● To audit the compliance with the

complaint handling procedures in accordance with this Manual and the Complaint

Management Plan;

● To verify the ET’s log-book and the

investigation result of any environmental exceedance, non-compliance and

complaint cases, compliance with the agreed Event and Action Plan and the

effectiveness of corrective actions / measures;

● To feedback audit results to the ET

by signing off relevant EM&A pro forma;

● To verify EM&A reports that have

been certified by the ETL;

● To audit EIA recommendations and requirements

against the status of implementation of environmental mitigation measures on

site;

● To report the works conducted, and

the findings, recommendations and improvements of the site inspections, after

reviewing ET’s and Contractor’s works, to the AAHK / PM on a monthly basis; and

● To review the effectiveness of the

EM&A programme, EIA recommendations and the adequacy of mitigation measures

implemented.

2

Air Quality Impact

2.1 Construction Air Quality Monitoring

2.1.1 General

2.1.1.1

The project is anticipated to give rise to construction dust impacts.

The key activities that would potentially result in dust emissions include land

formation works; construction works on the newly formed land and on the

existing airport island; operation of concrete batching plants, asphalt

batching plants, crushing plant, and barging points; haul roads; diversion of

submarine fuel pipeline; diversion of submarine 11 kV cable; and modifications

to existing outfalls. Construction phase dust monitoring is considered

necessary to check and ensure compliance that the relevant recommended

mitigation measures are properly implemented.

2.1.1.2

The key objectives of the construction phase dust monitoring are:

● To identify the extent of dust

impact during construction phase on sensitive receivers;

● To audit the compliance of the

Contractor with regard to dust control, contract conditions and the relevant

dust impact criteria;

● To determine the effectiveness of

mitigation measures to control fugitive dust emission from activities during

the construction phase;

● To recommend further mitigation

measures if found to be necessary; and

● To comply with Action and Limit

Levels for air quality as defined in this Manual.

2.1.2 Air Quality Parameters

2.1.2.1

Monitoring and audit of 24-hour

Respirable Suspended Particulates (RSP or PM10) and 24-hour Fine Suspended

Particulates (FSP or PM2.5) levels are not proposed. This is because even

under the hypothetical worst case Tier 1 mitigated scenario both 24-hour RSP

and 24-hour FSP would comply with the corresponding Air Quality Objectives

(AQO) at all Air Sensitive Receivers (ASR) throughout the construction period,

except the limited non-compliance with the AQO for 24-hour RSP at up to three

ASR in three of the eight construction years. Hence no significant RSP or FSP

impacts are anticipated. Therefore, only 1-hour Total Suspended Particulates

(TSP) will be monitored and audited at the proposed monitoring locations.

Details of the proposed monitoring locations are presented in Section 2.1.5

2.1.2.2

One-hour TSP levels shall be measured to indicate the impacts of

construction dust on air quality. The TSP levels shall be measured by following

the standard high volume

sampling method as set out in the Title 40 of the Code of Federal Regulations,

Chapter 1 (Part 50), Appendix B. Upon approval of

the AAHK / PM, as an alternative to using high volume sampling method, 1-hour

TSP levels can be measured by direct reading methods which are capable of

producing comparable results as that by the high volume sampling method, to

indicate short event impacts.

2.1.2.3

All relevant data including temperature, pressure, weather conditions,

elapsed-time meter reading for the start and stop of the sampler,

identification and weight of the filter paper, and any other local atmospheric

factors affecting or affected by site conditions etc. shall be recorded down in

detail. A sample data sheet is shown in Appendix

B. The ET may develop project specific

data sheet to suit this EM&A programme.

2.1.3 Monitoring Equipment

Technical Specifications as Presented in the Original EM&A Manual

2.1.3.1

High volume sampler (HVS) shall be used

for carrying out the 1-hour TSP monitoring.

2.1.3.2

The ET is responsible for provision of the monitoring equipment. They

shall ensure that sufficient number of samplers with an appropriate calibration

kit is available for carrying out the baseline monitoring, regular impact

monitoring and ad hoc monitoring. The samplers shall be equipped with an

electronic mass flow controller and be calibrated against a traceable standard

at regular intervals. All the equipment, calibration kit, filter papers, etc.

shall be clearly labelled.

2.1.3.3

Initial calibration of dust monitoring equipment shall be conducted upon

installation and thereafter at bi-monthly intervals. The transfer standard

shall be traceable to the internationally recognised primary standard and be

calibrated annually. The calibration data shall be properly documented for

future reference by the concerned parties such as the IEC. All the data shall

be converted into standard temperature and pressure condition.

2.1.3.4

The flow-rate of the sampler before and after the sampling exercise with

the filter in position shall be verified to be constant and be recorded down in

the data sheet as shown in Appendix

B.

2.1.3.5

If the ET proposes to use a direct reading dust meter to measure 1-hour

TSP levels, they shall submit sufficient information to the IEC to prove that

the instrument is capable of achieving a comparable result as that of the HVS

and may be used for the 1-hour sampling. The instrument shall also be

calibrated regularly, and the 1-hour sampling shall be determined periodically

by HVS to check the validity and accuracy of the results measured by direct

reading method.

2.1.3.6

Wind data monitoring equipment shall also be provided and set up at

conspicuous locations for logging wind speed and wind direction near to the

dust monitoring locations. The equipment installation location shall be

proposed by the ET and agreed with the IEC. For installation and operation of

wind data monitoring equipment, the following points shall be observed:

● The wind sensors shall be installed

on masts at an elevated level 10 m above ground so that they are clear of

obstructions or turbulence caused by the buildings;

● The wind data shall be captured by a

data logger. The data recorded in the data logger shall be downloaded

periodically for analysis at least once a month;

● The wind data monitoring equipment

shall be re-calibrated at least once every six months; and

● Wind direction shall be divided into

16 sectors of 22.5 degrees each.

2.1.3.7

In exceptional situations, the ET may propose alternative methods to

obtain representative wind data upon approval from the AAHK / PM and agreement

from the IEC.

Proposed Use of Portable Direct Reading Dust Meter and Existing Wind

Data from Chek Lap Kok Wind Station

2.1.3.8

Based on the provisions and

requirements set out in Section 2.1.3.5 above, a proposal of using

portable direct reading dust meter in undertaking the EM&A for the 3RS

project was submitted to the IEC, and agreement from the IEC was obtained. The

proposal concluded that the portable direct reading dust meter is capable to

provide comparable results of monitoring data as that provided by HVS, and with

the benefits of allowing prompt and direct results for the EM&A reporting.

The portable direct reading dust meter will be calibrated every year against

HVS to check the validity an accuracy of the results measured by direct reading

method.

2.1.3.9

On the other hand, the proposed use

of existing wind data from Chek Lap Kok Wind Station operated by HKO for wind

data collection instead of setting up a separate station near the existing

station was submitted to the IEC. Agreement from the AAHK / PM and IEC’s

approval was obtained.

2.1.4

Laboratory

Measurement / Analysis

2.1.4.1

A clean laboratory with constant temperature and humidity control, and

equipped with necessary measuring and conditioning instruments, to handle the

dust samples collected, shall be available for sample analysis, and equipment

calibration and maintenance. The laboratory should be the Hong Kong Laboratory Accreditation Scheme (HOKLAS) accredited or other internationally

accredited.

2.1.4.2

If a site laboratory is set up or a non-HOKLAS accredited laboratory is

hired for carrying out the laboratory analysis, the laboratory equipment shall

be approved by the AAHK / PM and the measurement procedures should be witnessed

by the IEC. Measurement performed by the laboratory shall be demonstrated to

the satisfaction of the AAHK / PM and the IEC. The IEC shall conduct regular

audit to the measurement performed by the laboratory to ensure the accuracy of

measurement results. The ET shall provide the AAHK / PM with one copy of the

Title 40 of the Code of Federal regulations, Chapter 1 (part 50), Appendix B

for his reference.

2.1.4.3

Filter paper of 8” X 10” shall be labelled before sampling of TSP. It

shall be a clean filter paper with no pin holes, and shall be conditioned in a

humidity controlled chamber for over 24-hour and be pre-weighed before use for

the sampling.

2.1.4.4

After sampling, the filter paper loaded with dust shall be kept in a

clean and tightly sealed plastic bag. The filter paper is then returned to the

laboratory for reconditioning in the humidity controlled chamber followed by

accurate weighing by an electronic balance with a readout down to 0.1 mg. The

balance shall be regularly calibrated against a traceable standard.

2.1.4.5

All the collected samples shall be kept in a good condition for six

months before disposal.

2.1.5

Monitoring Locations

Technical

Specifications as Presented in the Original EM&A Manual

2.1.5.1

Two separate air quality monitoring

locations are proposed and summarised in Table 2‑1.

The status and locations of dust sensitive receivers may change after issuing

this Manual. If such cases exist, the ET should propose updated monitoring

locations and seek agreement from EPD, and agreement from the AAHK / PM and IEC

before baseline monitoring commences.

Table 2‑1:

Construction Air Quality Monitoring Stations

|

ID |

ID Adopted in EIA |

Description |

Monitoring Parameters |

|

AR1 |

TC-13 |

Seaview Crescent Block 1 |

1-hour TSP |

|

AR2 |

ST-1 |

Village house at Tin Sum |

1-hour TSP |

2.1.5.2

When alternative monitoring locations are proposed, the following

criteria, as far as practicable, shall be followed:

● At the site boundary or such

locations close to the major dust emission source;

● Close to the sensitive receptors;

and

● Take into account the prevailing

meteorological conditions.

2.1.5.3

Monitoring equipment must be positioned, sited and orientated properly.

The ET should agree with the AAHK / PM in consultation with the IEC on the

position of the samplers for the installation of the monitoring equipment. When

positioning the samplers, the following points shall be noted:

● A horizontal platform with

appropriate support to secure the samplers against gusty wind shall be

provided;

● No two samplers shall be placed less

than 2 m apart;

● The distance between the sampler and

an obstacle, such as buildings, must be at least twice the height that the

obstacle protrudes above the sampler;

● A minimum of 2 m of separation from

walls, parapets and penthouses is required for rooftop samplers;

● A minimum of 2 m separation from any

supporting structure, measured horizontally is required;

● No furnace or incinerator flue is

nearby;

● Airflow around the sampler is

unrestricted;

● The sampler is more than 20 m from

the dripline;

● Any wire fence and gate, to protect

the sampler, shall not cause any obstruction during monitoring;

● Permission must be obtained to set

up the samplers and to obtain access to the monitoring stations; and

● A secured supply of electricity is

needed to operate the samplers.

2.1.5.4

The ET may, depending on site conditions and monitoring results, decide

whether additional monitoring locations should be included or any monitoring

locations could be removed / relocated during any stage of the construction

phase.

Updated Monitoring

Locations

2.1.5.5

Based on the provisions and

requirements set out in Sections 2.1.5.1 and 2.1.5.2 above, a

change in monitoring location was proposed for AR1 (Block 1 at Seaview

Crescent), and agreement was obtained from the AAHK / PM and IEC and EPD.

The location of the alternative monitoring station, AR1A, is shown in Drawing No. MCL/P132/EMA/2-001.

The location of the originally proposed monitoring location AR1 is also shown

in the same drawing for easy reference. Table 2‑2

summarises the updated locations of the construction air quality monitoring

stations.

2.1.5.6

A change of the monitoring location

in both the baseline and subsequent impact monitoring for AR1 was identified

necessary as access was not granted for setting up the onsite monitoring

station. The new monitoring location AR1A is situated in close proximity

to Seaview Crescent and it is also considered to be a representative location

for monitoring the construction phase air quality impact from the project.

Table 2‑2:

Updated Locations of Construction Air Quality Monitoring Stations

|

ID |

ID Adopted in EIA |

Description |

Monitoring Parameters |

|

AR1A(1) |

- |

Man Tung Road Park |

1-hour TSP |

|

AR2 |

ST-1 |

Village house at Tin Sum |

1-hour TSP |

Note: (1) alternative air quality monitoring

location

2.1.6 Baseline Monitoring

2.1.6.1

Baseline monitoring should be conducted at all designated monitoring

locations, see Table

2‑1, for at least 14 consecutive days

before commencement of construction work to obtain ambient 1‑hour TSP

samples. The commencement date of baseline monitoring shall be agreed between

the ET / IEC / AAHK / PM to ensure timely submission of the baseline monitoring

report to EPD. The selected baseline monitoring stations should reflect

baseline conditions at the stations. One-hour TSP sampling shall also be done

at least three times per day. The baseline monitoring will provide data for the

determination of the appropriate Action Levels with the Limit Levels set

against statutory or otherwise agreed limits. General meteorological conditions

(wind speed, wind direction and precipitation) and notes regarding any

significant adjacent dust producing sources should also be recorded throughout

the baseline monitoring period.

2.1.6.2

Before commencing the baseline monitoring, the ET shall inform the IEC

of the baseline monitoring programme such that the IEC can conduct on-site

audit to ensure accuracy of the baseline monitoring results. During the

baseline monitoring, there should not be any construction dust generating

activities in the vicinity of the monitoring stations.

2.1.6.3

In case the baseline monitoring cannot be carried out at the designated

monitoring locations during the baseline monitoring period, the ET shall carry

out the monitoring at alternative locations that can effectively represent the

baseline conditions at the impact monitoring locations. The alternative

baseline monitoring locations should be approved by the AAHK / PM and agreed

with the IEC.

2.1.6.4

In exceptional cases, when insufficient baseline monitoring data or

questionable results are obtained, the ET should liaise with the IEC and EPD to

agree on an appropriate set of data to be used as baseline reference and submit

to EPD for approval.

2.1.6.5

Ambient conditions may vary seasonally and should be reviewed once every

six months. If the ET considers that significant changes in the ambient

conditions have risen, a repeat of the baseline monitoring may be carried out

to update the baseline levels and air quality criteria after consultation and

agreement with the AAHK / PM, IEC and EPD. The monitoring should be undertaken

at times when Contractor’s activities are not generating dust, at least in the

proximity of the monitoring stations. Should change in ambient conditions be

determined, the baseline levels and, in turn, the air quality criteria, shall

be revised. The revised baseline levels and air quality criteria shall be

agreed with the IEC and EPD. If the ET considers that significant changes

in the ambient conditions have risen but a repeat of the 14-day baseline

monitoring is not found feasible due to the presence of ongoing construction

work, the ET may propose an alternative method for updating the baseline levels

and air quality criteria but this shall be subject to the agreement with the

IEC and EPD.

2.1.7 Impact Monitoring

2.1.7.1

The monthly schedule of the compliance and impact monitoring programme

should be drawn up by the ET one month prior to the commencement of the

scheduled construction period.

2.1.7.2

The ET should carry out impact monitoring throughout the entire course

of the Works. For 1-hour TSP monitoring, the sampling frequency of at least

three times in every six days should be undertaken when the highest dust impact

is expected to occur. Highest dust impacts will be determined by the actual

construction site condition, program and the works to be carried out. Before

commencing the impact monitoring, the ET should inform the IEC of the impact

monitoring programme such that the IEC can conduct on-site audit to ensure accuracy

of the impact monitoring results.

2.1.7.3

In case of non-compliance with the air quality criteria, more frequent

monitoring exercise, as specified in the Event and Action Plan, should be

conducted within 24 hours after the result is obtained. This additional

monitoring shall be continued until the excessive dust emission or the

deterioration in air quality is rectified.

2.1.8 Event and Action Plan

2.1.8.1

Baseline 1-hour TSP monitoring was conducted for 14 consecutive days

between 6 November 2015 and 27 November 2015 at two air quality monitoring

stations of AR1A and AR2. The Action Levels for 1-hr TSP during impact

monitoring are established based on the measured baseline TSP levels for

assessing the impact and compliance during the construction of the project. Table 2‑3 shows the air quality criteria, namely Action Level (AL)

and Limit Level (LL) to be used. Should non-compliance of the air quality

criteria occurs, actions in accordance with the Event and Action Plan in Table 2‑4 should

be carried out.

Table 2‑3:

Action and Limit Levels for Air Quality

|

Parameters |

Action Level [1]

|

Limit Level (µg/m3) |

|

1-hour TSP Level in µg/m3 |

For baseline level ≤ 384 µg/m3, Action Level = (130% of baseline level + Limit Level)/2 For baseline level ˃ 384 µg/m3, Action Level = Limit Level |

500 |

|

|

[1] According to the latest submission of

Baseline Monitoring Report approved by EPD, the Action Levels for AR1A and AR2

are 306 µg/m3 and 298 µg/m3 respectively.

Table 2‑4:

Event and Action Plan for Air Quality

|

Event |

ET |

IEC |

Action AAHK / PM |

Contractor |

|

Action Level |

|

|

|

|

|

1. Exceedance for one sample |

1. Identify source, investigate the causes of exceedance and propose remedial measures; 2. Inform IEC and AAHK / PM; 3. Repeat measurement to confirm finding; 4. Increase monitoring frequency to daily. |

1. Check monitoring data submitted by ET; 2. Check Contractor’s working method. |

1. Notify Contractor. |

1. Rectify any unacceptable practice; 2. Amend working methods if appropriate. |

|

2. Exceedance for two or more consecutive samples |

1. Identify source; 2. Inform IEC and AAHK / PM; 3. Advise the AAHK / PM on the effectiveness of the proposed remedial measures; 4. Increase monitoring frequency to daily; 5. Discuss with IEC and Contractor on remedial actions required 6. If exceedance continues, arrange meeting with IEC and AAHK / PM 7. If exceedance stops, cease additional monitoring. |

1. Check monitoring data submitted by ET; 2. Check Contractor’s working method 3. Discuss with ET and Contractor on possible remedial measures; 4. Advise AAHK / PM on the effectiveness of the proposed remedial measures; 5. Supervisor implementation of remedial measures. |

1. Confirm receipt of notification of failure in writing; 2. Notify Contractor; 3. Ensure remedial measures properly implemented. |

1. Submit proposals for remedial actions to IEC within three working days of notification; 2. Implement the agreed proposals; 3. Amend proposal if appropriate. |

|

Limit Level |

|

|

|

|

|

1. Exceedance for one sample |

1. Identify the source, investigate the causes of exceedance and propose remedial measures; 2. Inform AAHK / PM and Contractor. If the exceedance is valid, inform EPD; 3. Repeat measurement to confirm finding; 4. Increase monitoring frequency to daily; 5. Assess effectiveness of Contractor’s remedial actions and keep AAHK / PM, IEC and EPD informed of the results. |

1. Check monitoring data submitted by ET; 2. Check Contractor’s working method; 3. Discuss with ET and Contractor on possible remedial measures; 4. Advise AAHK / PM on the effectiveness of the proposed remedial measures; 5. Monitor the implementation of remedial measures. |

1. Confirm receipt of notification of failure in writing; 2. Notify Contractor; 3. Ensure remedial measures properly implemented. |

1. Take immediate action to avoid further exceedance; 2. Submit proposals for remedial actions to IEC within three working days of notification; 3. Implement the agreed proposals; 4. Amend proposal if appropriate. |

|

2. Exceedance for two or more consecutive sample |

1. Notify AAHK / PM, IEC, Contractor and EPD; 2. Identify source; 3. Repeat measurement to confirm finding; 4. Increase monitoring frequency to daily; 5. Carry out analysis of Contractor’s working procedures to determine possible mitigation to be implemented; 6. Arrange meeting with AAHK / PM and IEC to discuss the remedial actions to be taken; 7. Assess effectiveness of Contractor’s remedial actions and keep AAHK / PM, IEC and EPD informed of the results; 8. If exceedance stops, cease additional monitoring. |

1. Check monitoring data submitted by ET; 2. Check Contractor’s working method; 3. Discuss amongst AAHK / PM, ET, and Contractor on the potential remedial actions; 4. Review Contractor’s remedial actions whenever necessary to assure their effectiveness and advise AAHK / PM accordingly; 5. Monitor the implementation of remedial measures. |

1. Confirm receipt of notification of failure in writing; 2. Notify Contractor; 3. In consultation with IEC, agree with the Contractor on the remedial measures to be implemented; 4. Ensure remedial measures properly implemented; 5. If exceedance continues, consider what portion of the work is responsible and instruct the Contractor to stop that portion of work until the exceedance is abated. |

1. Take immediate action to avoid further exceedance; 2. Submit proposals for remedial actions to IEC within three working days of notification; 3. Implement the agreed proposals; 4. Resubmit proposals if problem still not under control; 5. Stop the relevant portion of works as determined by AAHK / PM until the exceedance is abated. |

2.1.9 Mitigation Measures

2.1.9.1

Appropriate dust suppression measures should be adopted as required under

the Air Pollution Control (Construction Dust) Regulation as well as the

Specified Process licences for the concrete batching plants, asphalt batching

plants and rock crushing plant. A control programme can be instigated to

monitor the construction process in order to enforce dust controls and modify

methods of works where feasible to reduce the dust emission down to acceptable

levels. The implementation schedule of the recommended air quality mitigation

measures is presented in Appendix

C.

2.2

Operational Air Quality Monitoring

2.2.1 General

2.2.1.1

The operational air quality impact

assessment presented as part of the EIA Report has concluded that the operation

of the project will not give rise to adverse residual air quality

impacts. The assessment findings for Year 2031 3RS scenario indicated

that cumulative NO2, RSP, FSP, SO2 and CO levels comply

with the relevant AQOs at all ASR. Nevertheless, to be prudent, it is proposed

that AAHK should carry out regular reviews of the operation phase air quality

monitoring results and relevant operation data in order to:

● Monitor the variations in pollutant

concentrations and compare these with the operation air quality assessment

results presented in the EIA Report;

● Determine the effectiveness of

AAHK’s measures and initiatives aimed at further reducing air pollutant

emissions from airport activities and operations; and

● Identify follow-up actions and / or

further investigation that may be undertaken where necessary with a view to

further reducing air emissions associated with the operation of the

project.

2.2.2 Regular Review of Air Quality

Monitoring Results

Existing Air

Quality Monitoring Stations

2.2.2.1

While the establishment of additional air quality monitoring station was

not identified necessary, the EIA Report recommended that the current airport

air quality monitoring stations shall be maintained. These include three

air quality monitoring stations (AQMSs) operated by AAHK, with one at Sha Chau

(SC) and two on the existing airport island, namely the North Station (PH1) and

South Station (PH5), as shown in Drawing No.

MCL/P132/EMA/2-002. The AQMS at

Tung Chung (TC) operated by EPD is also shown in the drawing.

2.2.2.2

The PH1 and PH5 stations are

positioned on the airport island close to the existing north runway (or the

future middle runway after the airport expansion) and the existing south runway

respectively; the SC station is over 2.8 km to the north of the expanded

airport island; while the TC station is located on the southeast side of the

airport island. This network of existing AQMSs is considered to be able to

provide representative monitoring data on the air quality on the expanded

airport island and its surrounding areas. Therefore, the AQMSs currently

operated by AAHK are to be maintained and the monitoring data obtained from

these stations should be used, together with that from the TC AQMS operated by

EPD, for regular reviews of the operation phase air quality.

2.2.2.3

Table 2-5 summaries the existing AQMSs operated by AAHK.

Table 2-5:

Operational Air Quality Monitoring

|

Station ID |

Station Name |

Location |

Operated by |

Monitoring Parameters |

|

SC |

Sha Chau |

Sha Chau |

Airport Authority |

Conc. of NO2, RSP, FSP, O3, SO2 and CO reported on hourly basis |

|

PH1 |

North Station |

Existing airport island |

Airport Authority |

Conc. of NO2, RSP, FSP, O3, SO2 and CO reported on hourly basis |

|

PH5 |

South Station |

Existing airport island |

Airport Authority |

Conc. of NO2, RSP, FSP, O3, SO2 and CO reported on hourly basis |

Existing Monitoring

Equipment

2.2.2.4 The existing monitoring equipment of NO2,

RSP, FSP, O3, SO2 and CO at the three AQMSs operated by

AAHK are summarised in Table 2-6. As the equipment may

be replaced due to certain period of utilisation, the monitoring equipment

shall be reviewed by the ET prior to the monitoring during operational phase of

the project.

Table

2-6:

The Existing Monitoring Equipment Adopted at South Station, North Station and

Sha Chau Station

|

Parameters |

Adopted Technique |

Existing monitoring equipment |

|

NO2 |

Gas Phase Chemiluminescence |

Ecotech EC9841B / Thermo Scientific 42i |

|

RSP |

Drawing air through a filter at a constant rate, continuously weighing the filter and calculating near real-time mass concentrations |

TEOM 1405DF Ambient Particulate Monitor |

|

FSP |

||

|

O3 |

Non-dispersive ultraviolet (UV) photometer |

Thermo Scientific 49i/ Ecotech EC9810B |

|

SO2 |

Ultraviolet Flourescence |

Thermo Scientific 43i/ Ecotech EC9850B |

|

CO |

Gas Filter Correlation photometry |

Thermo Scientific 48i/ Ecotech EC9830B |

Selection of Air Quality Parameters for Review

2.2.2.5

NOx is the key air pollutant

associated with airport operations. The source contribution breakdown for the

cumulative annual average NO2 impact at the key sensitive areas

under the 3RS scenario in the worst assessment year of 2031 presented in Table

5.5.2 of the EIA Report are reproduced in Table 2-7 below.

The dominant emission sources were identified to be from ambient emissions,

which contributed in most cases more than 60% of the total NO2

concentrations. This is followed by proximity infrastructure emissions

(10 – 30%) and airport-related emissions (< 10%), except for Sha Lo Wan.

Table 2-7:

Concentration Breakdown for the Cumulative Annual NO2 Impact at the

Key Sensitive Area under the 3RS scenario in Year 2031

|

Area |

ASR |

Airport Related Emission (µg/ m3) |

Proximity Infrastructure Emission (µg/ m3) |

Ambient (µg/ m3) |

Cumulative Impact (µg/ m3) |

|

Tung Chung |

TC-22 |

2 |

9 |

22 |

33 |

|

Tung Chung West |

TC-P7 |

2 |

6 |

22 |

30 |

|

Tung Chung East |

TC-P12 |

2 |

4 |

22 |

28 |

|

Sha Lo Wan |

SLW-1 |

12 |

4 |

20 |

36 |

|

Tuen Mun[1] |

TM-10 |

2 [1] |

9 |

27 |

38 |

Note:

[1] Airport related

emission is included in ambient in PATH model for Tuen Mun area

2.2.2.6

Based on the operational air quality

assessment findings presented in the EIA Report, NO2 is considered

as the key parameter for which the available monitoring data obtained at AAHK’s

AQMSs together with that obtained at EPD’s AQMS in TC should be regularly

reviewed during the operation phase of the project. The regular review shall

also analyse and present the measured NO and NOx concentrations for

estimating the pollutant contribution due to airport operations. To be prudent,

available monitoring data on RSP and FSP should also be included in the regular

reviews.

Frequency of Review

2.2.2.7

It is recommended that the first

review of NO2, RSP and FSP monitoring results should be carried out

after the first year of operation of 3RS. Regular review should then be carried

out at regular interval of at least every five years during the first 20 years

of operation of the project. The frequency of the reviews may be subject to

changes depending on the review results.

2.2.3

Operational Phase Air Quality Monitoring and Audit

Requirements

2.2.3.1

During the regular review of NO2,

RSP and FSP monitoring results, a detailed examination of the temporal and

spatial variations of pollutant levels measured at AAHK’s AQMSs shall be

presented and the analysis shall also take into consideration the available

monitoring data obtained at EPD’s AQMS in TC. With consideration of the

available data including those on meteorological conditions (i.e., wind

direction, wind speed, temperature, precipitation, etc), the review shall

characterise the mean seasonal and diurnal variation of pollutant concentrations,

with a view to evaluating the significance of the contribution of air quality

impact from airport emissions on the nearby air sensitive receivers. Also, the

regular review shall include the compilation of an updated inventory of major

emission sources, including emissions from aircraft landing take-off (LTO)

cycle, associated with the airport operations. AAHK shall collect the relevant

information for development of the latest airport emissions inventory as part

of the review.

2.2.3.2

As part of the regular review, the

effectiveness of existing measures and initiatives implemented by AAHK aimed at

further reducing air pollutant emissions from airport operation shall also be

evaluated. Follow-up actions and/or further investigation work that may

be undertaken where necessary with a view to further reducing air emissions

associated with the operation of the project should be recommended as part of

the regular review.

2.2.3.3

The detailed air quality monitoring

and auditing requirements should be presented as part of the Airport Operation

related Emissions Control Plan that shall be submitted no later than 3 months

before the operation of the project in accordance to EP Condition 2.24.

3

Hazard to Human Life

3.1

Introduction

3.1.1.1

A hazard identification workshop has been conducted in the EIA Report to

identify potential hazards associated with the construction and operation phase

of the project. Mitigation measures have also been explored to prevent the hazards

from happening and they will be implemented in the project.

3.1.1.2

A hazard assessment has been

conducted in the EIA Report which concluded that the risk level for the

construction phase is within the acceptable region and mitigation measure is

not required. The risk level for the operation phase has been evaluated to be

in As Low As Reasonably Practicable (ALARP) region and the major risk

contributor is aircraft refuelling operation. Practicable and cost effective

mitigations have been proposed to reduce the risk of aircraft refuelling

operation.

3.2

Recommendation

3.2.1.1

The recommended measures as outlined in the Implementation Schedule

included as Appendix

C in this EM&A Manual should be

implemented to meet the Technical Memorandum on Environmental Impact Assessment

Process (EIAO-TM) requirements.

4

Noise Impact

4.1 Aircraft Noise Monitoring

4.1.1 Aircraft Noise Monitoring and Audit

Requirements

4.1.1.1

As per the requirements set out in

Section 7, Appendix C of the EIA Study Brief, the aircraft noise monitoring and

audit plan shall:

● Provide data and information for

verifying predictions on the effectiveness of measures to mitigate aircraft

noise impact of the project;

● Formulate audit requirements,

including any necessary compliance and post-project audit program, in order to

review the monitoring data and identify any remedial works, as necessary,

required to address unacceptable or unanticipated aircraft noise impacts; and

● Provide tools, procedures and

supplementary information, including noise descriptor and flight tracks, which

are useful and relevant for communicating the aircraft noise of the project to

the general public.

4.1.1.2

The Procedures for Mitigation of

Aircraft Noise that shall be submitted no later than 3 months before the

operation of the project in accordance to EP Condition 2.21.

4.1.2 Program Elements

4.1.2.1

Taking into account the EIA Study

Brief requirements as described above, it is proposed that the aircraft noise

monitoring and audit plan should consist of the following key elements:

● An exercise by AAHK to verify

predictions on the effectiveness of measures to mitigate aircraft noise impact

and the preparation of a Prediction Verification Report;

● Review Report, prepared on an annual

basis by AAHK, for detailing the compliance with noise abatement procedures and

unanticipated events, as well as any further necessary investigation and/or

remedial action(s); and

● Noise Contour Report, prepared in at

least every five years by AAHK, to compare actual airport operation to forecast

airport operation with respect to aircraft noise, taking into account data

collected on actual aircraft operational levels, fleet mix, runway and flight

track utilizations; and produce an updated noise contour using the most

currently available and internationally accepted noise modelling methodology.

4.1.2.2

In additional to the above reporting

requirements, AAHK shall continue to engage with the neighbouring communities

in the vicinity of HKIA, other stakeholders and interested parties on aircraft

noise issues associated with the operation of the project.

4.1.3 Prediction Verification

4.1.3.1

The purpose of this task is for

verification of predictions on the effectiveness of measures to mitigate

aircraft noise impact of the project. This verification exercise shall be

undertaken upon availability of relevant airport operation data for the first

full year operation of the third runway of the project. A Prediction

Verification Report, certified by the ETL and verified by the IEC, shall be

submitted to EPD for approval.

4.1.3.2

As part of the prediction

verification exercise, AAHK should collect radar data showing airport and

flight operations for the first full year operation of the proposed third

runway from Civil Aviation Department (CAD). Based on the radar data

collected, the AAHK should carry out aircraft noise contour simulation.

Similar approach adopted to process radar data for the prevailing scenario contour

as presented in Chapter 7 of the EIA Report might be applied (individual radar

data be pre-processed and annual daily average noise contours be produced by

Integrated Noise Model (INM) for daily results) and the detailed methodology

shall be agreed with EPD. The computational model to be used shall also

be agreed with EPD prior to the analysis.

4.1.3.3

The Noise Exposure Forecast (NEF) 25

contour prepared based on radar data should be compared against the noise

contours presented in Chapter 7 of the EIA Report for verifying the

effectiveness of measures to mitigate the aircraft noise impact of the

project. If the comparison of contours shows a reasonable converge, this

would imply the aircraft noise prediction by computer simulation with forecast,

assumptions and proposal of mitigation measures would reliably reflect that by

actual airport and flight operations. In case discrepancies are observed,

explanation shall be given and analysed as part of the Prediction Verification

Report.

4.1.3.4

It shall be noted that the noise

contours presented in Chapter 7 of the EIA Report are based on reasonable

assumptions and input data including air traffic forecast, runway mode of

operation, flight tracks and flight track utilisation, and proposed mitigation

measures. Therefore, whilst it is being compared with the one generated

by actual airport and flight operations, variances within reasonable ranges are

envisaged and considered acceptable. Having said that, it is essential to

ensure that with the mitigation measures recommended in the EIA Report, no

additional noise sensitive receivers should be subject to adverse environmental

impact under the requirements of the EIAO-TM. Detailed examination should

be followed especially for those areas with major variances and the underneath

rationale(s) will be elaborated.

4.1.4 Review Report

4.1.4.1

The Review Report, prepared on an

annual basis by AAHK shall include an analysis of how well aircraft flight

follow each of the aircraft noise mitigation measures recommended in Chapter 7

of the EIA Report. Information to be collected shall include available

radar data showing airport and flight operations from CAD, and this is to be

analysed in terms of flight tracks and runway utilisation for checking the

effective implementation of the noise reduction measures. AAHK may make

references to available operational noise data collated by the relevant

authorities. Wind record in the year should also be collected from HKO.

The Review Report should review the data collected including measured noise

levels at representative locations, statistics of flight tracks, flight tracks

dispersion and aircraft using proposed mitigation measures and existing noise

mitigation measures, etc.

4.1.4.2

The annual review and reporting process

will allow AAHK to measure exactly how it stands compared to predicted

operations used in the preparation of the EIA Report. If there are any major

variances / discrepancies / abnormalities that are observed during the ongoing

process of data collection and analysis for preparation of the annual review

when compared with the assumptions / measures adopted in the assessment, early

investigation shall be carried out for identification of the possible causes of

the variances / discrepancies / abnormalities and whether these would

significantly affect the aircraft noise environment.

4.1.5 Noise Contour Report

4.1.5.1

As the aircraft noise impact

assessment was undertaken on the basis of projected air traffic movements and

estimated fleet mix, it is recommended that at regular intervals of at least

every five years during the first 20 operational years of the project, actual

flight data obtained from local Air Traffic Control radar systems should be

acquired and analysed with a similar aircraft noise modelling methodology to

confirm the representativeness of the earlier noise analyses. The first Noise

Contour Report shall be prepared upon availability of the airport operation

data for the first full year operation of the third runway of the project. In

accordance with the requirements set out in Condition 2.22 of the EP, an

updated NEF 25 contour shall also be submitted no later than 3 months after a

full year of operation of the 3RS project. Similar approach adopted to process

radar data for prevailing scenario contour might be applied and the detailed

methodology shall be agreed with EPD.

4.1.5.2

At such time that it is determined

that the noise contours obtained using actual airport data may start to

encroach onto any additional noise sensitive receivers, or when it is

considered that there are major deviations from the assumptions adopted in the

EIA Report, additional analysis would be necessary to update the NEF 25

contour. The need and feasibility of introducing additional mitigation

measures should also be assessed to ensure that no adverse environmental impact

would be resulted from the implementation of the project with respect to

aircraft noise.

4.1.6 Community Liaison

4.1.6.1

AAHK has been actively engaging with

neighbouring communities in the vicinity of the airport, other stakeholders

groups and interested parties to communicate issues and gauge views on aircraft

noise and other environmental aspects. Briefings and airport visits are

organised to explain subjects including but not limited to flight paths under

the planned 3RS and the proposed aircraft noise mitigation measures. These

engagement activities will continue after commencement of the project and a

community liaison plan that presents details of the planned programme,

including proposed communication channels, tools, procedures and supplementary

information, including noise descriptor and flight tracks in accordance with

Section 7.3, Appendix C of the Study Brief and activities that would facilitate

communications with stakeholders on aircraft noise issues, will be developed by

AAHK as part of the detailed Aircraft Noise Monitoring and Audit Plan presented

in Section 4.1.7 below.

4.1.7 Detailed Aircraft Noise Monitoring

and Audit Plan

4.1.7.1

The above subsections set out a clear

EM&A framework with respect to aircraft noise. It is not yet mature

to define all the monitoring and audit details as at the course of assessment

whilst the EM&A task will only be started with operation commencement of

the third runway of the project because computation model and data analysis

tools are in rapid evolution nowadays.

4.1.7.2

Prior to commencement of project operation,

a detailed Aircraft Noise Monitoring and Audit (ANM&A) Plan, proposing (i)

work programme; (ii) actual data collection; (iii) methodologies / procedures,

including proposed computation model, to process data into indicators of

measures / assumptions adopted; (iv) quality control and assurance procedure;

(v) action / investigation plan if any non-compliance, including associated

Action and Limit Levels; (vi) community liaison plan; (vii) relevant proforma

forming part of the reports; (viii) any foreseeable uncertainties, etc, should

be submitted to EPD for agreement.

4.1.7.3

In accordance with the requirements

set out in EP Condition 2.23, the ANM&A Plan shall include information on

aircraft noise monitoring at representative locations in Tung Chung, Ma Wan,

Tsing Yi, Tsuen Wan, Ting Kau, Siu Lam and Tuen Mun. The ANM&A Plan shall

make use of available aircraft noise and flight track monitoring data including

measured noise levels in terms of dB(A) and their distribution, flight tracks, aircraft

fleet mix data and other relevant information at the above-mentioned locations.

The ANM&A Plan shall also include an action plan, as approved by

Director-General of Civil Aviation, to review the noise data to assess the

effectiveness of the mitigation measures and to take appropriate action with

reference to the prevailing internationally recognised standards in aircraft

noise mitigation.

4.1.7.4

Before submission to the Director of

Environmental Protection for approval, the ANM&A Plan shall be certified by

the ETL and verified by the IEC as conforming to the information and

recommendations described in the EIA Report, and taking into account any

specific requirements with respect to the latest in-situ conditions of the

project.

4.1.7.5

When developing the detailed plan,

references should be made to relevant international guidelines such as SAE

ARP4721 Part 1 – Monitoring Aircraft Noise and Operations in the Vicinity of

Airports: System Description, Acquisition, and Operation, if applicable, for

the purpose of review and describe the project operation. The latest monitoring

and audit practice / presentation adopted by similar international airports

should be reviewed and reference during the course of preparation of this

detailed plan.

4.2

Fixed

Noise Sources Monitoring

4.2.1 Maximum Permissible Sound Power

Levels of Fixed Plant

4.2.1.1

The maximum permissible sound power

levels of the identified fixed noise sources of the project were predicted in

the EIA Report. The specified sound power levels should be

implemented and refined by the Contractor as appropriate to ensure that the

noise impact associated with the fixed plant operations would comply with the

noise standards stipulated in the EIAO-TM and Noise Control Ordinance (NCO).

4.2.2 Commissioning Test

4.2.2.1

Prior to the operation of the

project, the Contractor should conduct noise commissioning tests for all major

fixed plant noise sources (excluding the ground noise sources associated with

the aircraft taxiing and the operation of auxiliary power units (APUs)) within

HKIA to ensure the noise emission at the fixed plant noise source comply with

the EIA Report assessed scenario. The test should be carried out by a

qualified person possessing at least seven years of noise control experience

and a corporate membership of Hong Kong Institute of Acoustics or

equivalent. The noise commissioning test report should be submitted

to the AAHK / PM, ET and IEC for approval. The ET and IEC should review design

changes to ensure the cumulative noise impact from fixed noise sources comply

with the EIA Report assessed scenario.

4.2.2.2

Noise commissioning tests are also

required for noise enclosure of aircraft engine run-up facilities. ISO 10847 –

In-situ determination of insertion loss of outdoor noise barriers of all types

shall be employed to ensure the required noise reduction (insertion loss) in

the EIA Report (at least 15 dB(A)) would be achieved. The test should be

carried out by a qualified person possessing at least seven years of noise

control experience and a corporate membership of Hong Kong Institute of

Acoustics or equivalent. The noise commissioning test report should be

submitted to the AAHK / PM, ET and IEC for approval.

4.2.2.3

No adverse noise impacts are

anticipated from aircraft taxiing and APU operation, hence no environmental

monitoring and audit is proposed.

4.2.3 Mitigation Measures

4.2.3.1

The relevant noise mitigation

measures have been recommended in the EIA Report. The implementation

schedule of the mitigation measures is given in Appendix

C.

4.3

Construction

Airborne Noise Monitoring

4.3.1 Noise Parameter

4.3.1.1

The construction noise level should be measured in terms of the

A-weighted equivalent continuous sound pressure level (Leq). Leq(30

minutes) should be used as the monitoring parameter for the time period

between 0700-1900 hours on normal weekdays. For all other time periods, a

Construction Noise Permit (CNP) under the NCO would apply.

4.3.1.2

As supplementary information for data auditing, statistical results such

as L10 and L90 should also be obtained for reference. A

sample data record sheet based on the one presented in the “EM&A Guidelines

for Development Projects in Hong Kong” is shown in Appendix

B for reference.

4.3.2 Monitoring Equipment

4.3.2.1

As referred to in the Technical Memorandum (TM) issued under the NCO,

sound level meters in compliance with the International Electrotechnical

Commission Publications 651:1979 (Type 1) and 804:1985 (Type 1) specifications should

be used for carrying out the noise monitoring. Immediately prior to and

following each noise measurement the accuracy of the sound level meter should

be checked using an acoustic calibrator generating a known sound pressure level

at a known frequency. Measurements may be accepted as valid only if the

calibration level from before and after the noise measurement agrees to within

1.0 dB.

4.3.2.2

Noise measurements should be made in accordance with standard acoustical

principles and practices in relation to weather conditions. Handheld wind meter should be used for measuring and

checking the wind speed (in m/s) during the noise monitoring.

4.3.2.3

The ET is responsible for the

availability of monitoring equipment and should ensure that sufficient noise

measuring equipment and associated instrumentation are available for carrying

out the baseline monitoring, regular impact monitoring and ad hoc monitoring.

All the equipment and associated instrumentation should be clearly labelled.

4.3.3 Monitoring Locations

Technical Specifications as Presented in the Original EM&A Manual

4.3.3.1

The noise monitoring locations are

summarised in Table 4‑1. The status and

locations of noise sensitive receivers may change after issuing this manual. If

such case exists, the ET should propose updated monitoring locations and seek

approval from the AAHK / PM and agreement from the IEC and EPD of the proposal.

Table 4‑1:

Construction Noise Monitoring Stations

|

ID |

ID adopted in EIA |

Description |

|

NM1 |

TC-1 |

Seaview Crescent Block 1 |

|

NM2 |

TC-5 |

Tung Chung West Development (Monitoring to start after occupation of development in 2023/24, subject to the construction programme of the project) |

|

NM3 |

TC-30 |

Ho Yu College |

|

NM4 |

TC-37 |

Ching Chung Hau Po Woon Primary School |

|

NM5 |

TS-1 |

House, Tin Sum |

|

NM6 |

SLW-1 |

House No. 1, Sha Lo Wan |

4.3.3.2

When alternative monitoring locations are proposed, the monitoring

locations should be chosen based on the following criteria:

● Monitoring at sensitive receivers close

to the major site activities which are likely to have noise impacts;

● Monitoring at the noise sensitive

receivers as defined in the Technical Memorandum; and

● Assurance of minimal disturbance to

the occupants during monitoring.

4.3.3.3 The monitoring station should normally be at a point 1

m from the exterior of the sensitive receivers building facade and be at

position 1.2 m above the ground. If there is a problem with access to the

normal monitoring position, an alternative position may be chosen, and a

correction to the measurements should be made. For reference, a correction of

+3 dB(A) should be made to the free field measurements. The ET should agree

with the IEC on the monitoring position and the corrections adopted. Once the positions

for the monitoring stations are chosen, the baseline monitoring and the impact

monitoring should be carried out at the same positions.

Updated Monitoring

Locations

4.3.3.4

Based on the provisions and requirements

set out in Sections 4.3.3.1 and 4.3.3.2 above, a change in

monitoring location was proposed for NM1, NM2 and NM3. Agreement from the

AAHK / PM, IEC and EPD’s approval were obtained for the changes. The locations

of the alternative monitoring stations, including NM1A, NM2* and NM3A, are

shown in Drawing No.

MCL/P132/EMA/4-001. The locations of the originally proposed monitoring

locations (NM1, NM2 and NM3) are also shown in the same drawing for easy

reference. Table 4‑2 summarises the updated

locations of the construction noise monitoring stations.

4.3.3.5

The noise monitoring location in both

the baseline and subsequent impact monitoring for NM1 was changed to NM1A as

access to NM1 was not granted for setting up an onsite monitoring station.

4.3.3.6

The noise monitoring location in both

the baseline and subsequent impact monitoring for NM3 was changed to NM3A also

as access to NM3 was not granted for setting up an onsite monitoring station.

Moreover, when construction works of Tung Chung East Development near NM3A is

in place, the monitoring will be temporary suspended with duration subjected to

the programme of the development works and actual site conditions, and will be

resumed when the development works is completed. Actual arrangement of this

station will be reflected in relevant Monthly EM&A Reports.

4.3.3.7 Baseline noise monitoring at NM2 was undertaken at

NM2* as Tung Chung West Development had not yet been constructed. When the

future residential buildings in Tung Chung West Development become occupied,

the impact monitoring would be carried out at a representative location with

noise sensitive land uses and the exact location will be proposed by the ET for

agreement with the IEC and EPD prior to commencement of the impact monitoring.

Table 4‑2:

Construction Noise Monitoring Stations

|

ID |

ID adopted in EIA |

Description |

|

NM1A(1) |

- |

Man Tung Road Park |

|

NM2*(1) / NM2 |

TC-5 |

Tung Chung Battery* / Tung Chung West Development (Monitoring to start after occupation of development in 2023/24, subject to the construction programme of the project) |

|

NM3A(1) |

- |

Site Office at the northern edge of the reclaimed land (Monitoring to be temporarily suspended during construction works of Tung Chung East Development subject to programme of the works and actual site conditions) |

|

NM4 |

TC-37 |

Ching Chung Hau Po Woon Primary School |

|

NM5 |

TS-1 |

House, Tin Sum |

|

NM6 |

SLW-1 |

House No. 1, Sha Lo Wan |

Note: (1)

alternative noise monitoring location

4.3.4 Baseline Monitoring

4.3.4.1

The ET should carry out baseline noise monitoring prior to the

commencement of the project-related construction activities. The baseline

monitoring should be carried out daily for a period of at least two weeks. The

commencement date of baseline monitoring shall be agreed between the ET / IEC /

AAHK / PM to ensure timely submission of the baseline monitoring report to EPD.

Before commencing the baseline monitoring, the ET should develop and submit to

the IEC the baseline monitoring programme such that the IEC can conduct on-site

audit to check accuracy of the baseline monitoring results.

4.3.4.2

There should not be any construction activities in the vicinity of the

stations during the baseline monitoring.

4.3.4.3

In exceptional cases, when insufficient baseline monitoring data or

questionable results are obtained, the ET should liaise with the AAHK / PM, IEC

and EPD to agree on an appropriate set of data to be used as a baseline

reference and submit to the AAHK / PM and IEC for agreement and EPD for

approval.

4.3.5 Impact Monitoring

4.3.5.1

Noise monitoring should be carried out at all the designated monitoring

stations when there are project-related construction activities undertaken. The

monitoring frequency should depend on the scale of the construction activities.

The following is an initial guide on the regular monitoring frequency for each

station on a weekly basis when noise generating activities are underway:

● One set of measurements between

0700-1900 hours on normal weekdays.

4.3.5.2

If construction works are extended to include works during the hours of

1900-0700 as well as public holidays and Sundays, additional impact monitoring

(including monitoring locations) during respective periods of restricted hours

should be subject to the CNP requirements by EPD. Applicable permits under NCO

should also be obtained by the Contractor.

4.3.5.3

For schools located near the HKIA

(e.g. NM4), noise monitoring should be carried out at the monitoring stations

for the schools during the school examination periods. The ET should liaise

with the school’s personnel and the Examination Authority to ascertain the

exact dates and times of all examination periods during the course of the

contract.

4.3.5.4

In case of non-compliance with the construction noise criteria, more

frequent monitoring, as specified in the Event and Action Plan in Table 4‑4, should be carried out. This additional monitoring

should be continued until the recorded noise levels are rectified or proved to

be irrelevant to the construction activities.

4.3.6 Event and Action Plan for Noise

4.3.6.1

The Action and Limit Levels for construction noise are defined in Table 4‑3. Should non-compliance of the criteria occur, action in

accordance with the Event and Action Plan in Table 4‑4, should be carried out.

Table 4‑3:

Action and Limit Levels for Construction Noise

|

Time Period |

Action |

Limit |

|

0700-1900 hours on normal weekdays |

When one valid documented complaint is received. |

75* dB(A) |

Note:

* reduce to 70 dB(A) for schools and 65 dB(A) during school examination

periods.

Table 4‑4: Event and Action Plan

for Construction Noise

|

Event |

ET |

IEC |

Action AAHK / PM |

Contractor |

|

|

Action Level |

1. Notify AAHK / PM, IEC and Contractor; 2. Carry out investigation; 3. Report the results of investigation to the AAHK / PM, IEC and Contractor; 4. Discuss with IEC and Contractor on remedial measures required; 5. Increase monitoring frequency to check mitigation effectiveness. |

1. Review the investigation results submitted by the ET; 2. Review the proposed remedial measures by the Contractor and advise the AAHK / PM accordingly; 3. Advise AAHK / PM on the effectiveness of the proposed remedial measures. |

1. Confirm receipt of notification of failure in writing; 2. Notify Contractor; 3. In consolidation with IEC, agree with the Contractor on the remedial measures to be implemented; 4. Supervise the implementation of remedial measures. |

1. Submit noise mitigation proposals to AAHK / PM and IEC; 2. Implement noise mitigation proposals. |

|

|

Limit Level |